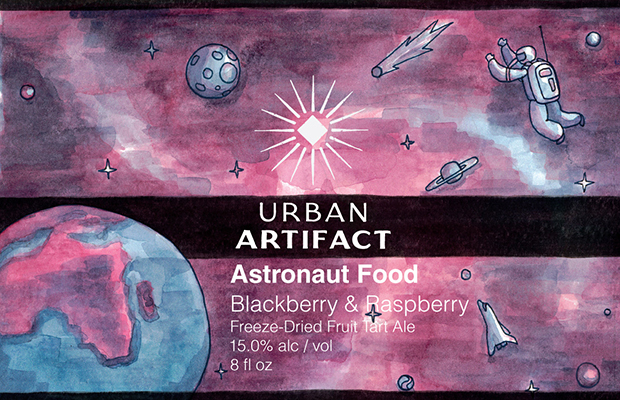

A more powerful fruit intensity coupled with a high ABV, Urban Artifact’s Astronaut Food is a new line of product from the Cincinnati brewery that strives to create what they call a ‘Midwest Fruit Tart’ lineup of beers.

The reason for the name Astronaut Food is that the brewery has been experimenting with freeze-dried fruit versus using fruit purees. The addition of a centrifuge in January has been a catalyst to the announcement that the first beer will be released in March.

Freeze-dried fruit reduces water weight by 90%, which makes the same amount of fruit — in this case, 1,000 pounds — be 11 times greater than 1,000 pounds of fruit puree through a process called sublimation, while the nutrients and taste remain.

This first release is made with 600 lbs of freeze-dried red raspberries and 400 lbs of freeze-dried blackberries per 1,000-gallon batch, the equivalent of 11,000 lbs of fruit when fresh.

UA’s Bret Kollmann Baker is the brewery’s Head of Brewing Operations and he shared with Brewer about sourcing and brewing with the substance.

Sourcing

“Who buys 1,000 pounds-plus of freeze-dried fruit at a time? Not a lot of customers, that is who,” Baker said. Urban Artifact had to get specialty production runs scheduled and was committed to buying them on contract.

Pricing is also ludacris, he added

“It’s over $25/lb for freeze-dried fruit, and the equivalent would be over $2/lb for fresh/frozen/puree, which is about double our price target of $1/lb for fruit,” Baker said. “So not only is the equivalent “wet” fruiting rate with freeze-dried at about 11lbs/gal, but we are also paying double the cost per equivalent “wet” pound.”

To lay out the numbers in a more stark contrast: A 1,000-gallon batch of fruit puree runs Urban Artifact about $3,000. A 1,000-gallon batch of freeze-dried fruit ran them $25,000.

Techniques

Being that the fruit comes as a powder, Baker said it’s not easy to get the fruit to dissolve, and since they didn’t want to heat it at all — being that it’s freeze-dried — that means all that powder needs to go into the tank during fermentation.

“Volume loss is high, as we are adding dry powder that soaks up beer,” he said. “We do have a centrifuge that will help with that though.”

In addition to the fruit-related dosing issues, there is also the matter that this is a 15% ABV beer, and with it comes high ABV fermentation woes such as stepped nutrient additions, multiple O2 and stirring events, and a slower fermentation and maturation process.

Sales

The 15% ABV beer will be sold in 8-ounce cans. Co-owner and Chief of Strategic Development, Scotty Hunter, told Brewer that UA has sold the size before with a wine-beer hybrid series.

”While ABV does have an impact on our choice of can size, there is also the consideration of how much a pack of beer will cost on the shelf,” Hunter said. “If we did this run in 12-ounce cans we would be looking at a retail of $37.99 to hit the same relative cost per ounce.

“Those two pieces are what lead to the use of these 8-ounce cans and while they will be sold in 4-packs we expect them to get singled out by many retailers.”

Be the first to comment