Keeping an eye on analytics along with good business acumen is essential for a sales team to develop a strategy for SKU management, keeping the consumers always in mind.

From the sales side, this means a weekly check-in with all distributors. For Ecliptic Sales Manager Erin Grey Kemplin, that means looking at ROS along with all seasonal series beer on order.

“I work with purchasers to either add or cut beer if needed so that we can run out at the right time,” she explained. “We are trying to ideally have the current seasonal go out of stock right as the new one is coming into inventory.”

Kemplin will send a weekly report to the Portland brewery’s operations team to summarize her finds and point out any possible issues.

“This is actually the hardest job to do of any SKU management at Ecliptic,” she said.

Assigning a unique identifier to each separate brand a brewery brews makes tracking every last item associated with that brand much easier.

“Have this 2- or 3-digit code embedded into the SKU of each pack type of finished goods, packaging materials, or even any other raw materials that might be unique to a specific brand,” said Capital Brewery‘s Ashley Kinart. “Running and searching through reports becomes a little easier and less of a headache.”

READ MORE: Are You Annoying Your Distributor Right Now?

As for planning for growth, Karben4‘s Zak Koga said he personally reviews the sale and inventory of every package size of every brand of the Karben4 brand every week.

“We lock in our production schedule for the very next week based on that real-time demand,” he said. “It is not a perfect system, especially when we are experimenting with new packages, but this gives us a very strategic advantage in executing new SKUs.

“The information we get every year helps us write a better beer calendar for the next year and engineer growth by maximizing the revenue velocity of the different seasonals.”

Koga said his team is believers in narrowing down the number of SKUs offered at any given time to offer just enough variety to the consumer while also adding a lot of value for their retail partners.

“If every SKU we put out has a great turn on the shelf then we are going to have a lot easier time keeping that shelf space and reaching all of our customers,” he said. “That’s the goal at least.”

Chris Lutkowski, who was the Hi-Wire Brewing‘s Director of Sales at the time of the interview with Brewer, said keeping track of inventory can come down to two questions that you can ask:

- What’s going on in the market/what is the consumer purchasing? “[It’s] tough to force the consumer what to drink — especially if it’s a flat or older style — but customers lately have been willing to try new things. If your product is good, you’ll get repeat purchases.”

- What do your trends look like for that same style/package? “If there’s a hot style that’s trending up and you’ve got one going the opposite direction, [it] will probably tell you something about the quality and/or the support for the brand. [It may be] time to retool or punt at that point.”

Lutkowski added that breweries need to understand what they’ve produced in the past for each SKU and what’s going on with that style out in the market.

“I’ll then reach out to all of my wholesalers and get their feedback as to how much they think they’ll sell and we typically meet somewhere in the middle,” he explained. “I would say planning in advance and open communication about expectations are the key to be successful in this area.”

Ecliptic has a lot of rotating UPCs yet Kemplin said they set up new items for each individual beer at all distributors.

Having the same UPC makes it easier for the retailer but having individual new items makes it easier for the distributors, she pointed out.

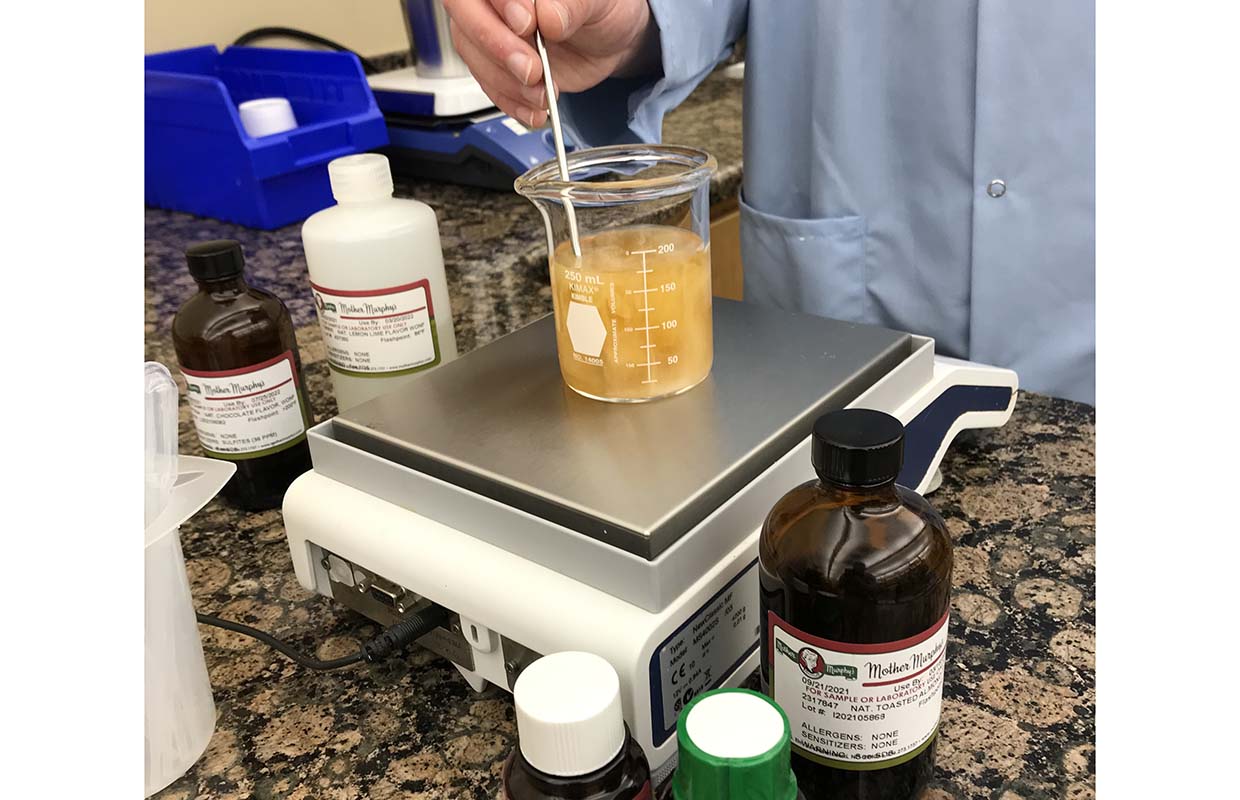

Photo courtesy Ecliptic Brewing

Be the first to comment