Keeping the see-saw of year-round and being creative with one-offs and seasonals can be a challenge as your brewery grows.

Keeping an eye to analytics along with a good business acumen are essential for a sales team to develop a strategy for SKU management, keeping the consumers always in mind.

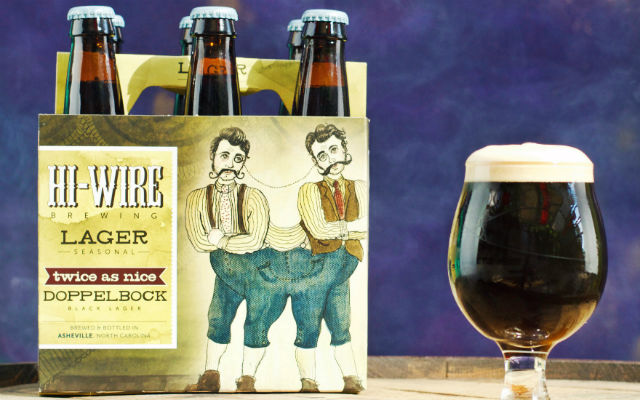

Chris Lutkowski, Hi-Wire Brewing‘s Director of Sales said keeping track of inventory can come down to two questions that you can ask:

- What’s going on in the market/what is the consumer purchasing? “[It’s] tough to force the consumer what to drink — especially if it’s a flat or older style — but customers lately have been willing to try new things. If your product is good, you’ll get repeat purchases.”

- What do your trends look like for that same style/package? “If there’s a hot style that’s trending up and you’ve got one going the opposite direction, [it] will probably tell you something about the quality and/or the support for the brand. [It may be] time to retool or punt at that point.”

Devils Backbone has two rotating lineups, the Daypack Series and the Trailblazers. The Daypack beers are quick, easy, and mobile. Quick because they have approachable flavor profiles; easy, because they are all under 4.5%; and mobile, because they are all canned. The Trailblazers are all higher ABV, with more aggressive and assertive flavor profiles. Each lineup lives within a single UPC, which allows the brewery to offer the consumer nine different beers, while just asking for two spots on the shelf.

“In terms of managing these SKUs, well, I’d be lying if I said it was easy or we were good at it,” COO Hayes Humphreys told Brewer in a recent story. “The two main challenges for us are over production and transitions between brands.”

In terms of production quantities, he noted, generally a brewery wants to plan to run out. Forecast conservatively is the ideal.

“However, in a state where the retail landscape is dominated by chains like Virginia, running out too soon can cause out of stock issues and make it look like your packages aren’t pulling their weight,” he added. “So, it’s a real balancing act. We still run primarily off of forecasts. We have found that wholesalers are extremely conservative forecasters, so that even when we take pre-orders on items, we end up having to guesstimate a reserve to account for wholesalers who run out too early, which means that for us, it’s really hard to eliminate risk.”

Lutkowski added that breweries need to understand what they’ve produced in the past for each SKU and what’s going on with that style out in the market.

“I’ll then reach out to all of my wholesalers and get their feedback as to how much they think they’ll sell and we typically meet somewhere in the middle,” he explained. “I would say planning in advance and open communication about expectations are the key to be successful in this area.”

3 Trackbacks / Pingbacks