When it comes to keeping a quality and consistent beer on the shelf and in the keg, BridgePort Brewing’s Jeff Edgerton said slow and steady wins the race.

“I think that the most common pitfall that I’ve seen among new brewers is thinking that making good beer is easy and fast,” the Portland Brewmaster told Brewer Magazine. “Trying to rush the process or skip steps to get beer into package faster is always a mistake.”

A mis-step in that process can lead to bad batches. If a customer comes across that batch in an already crowded marketplace, it could mean a loss of cash flow for the future.

“The results of the testing is very important and we always look at those, but in the end, it’s how the product is perceived by your customers,” Edgerton said. “We listen when our customers tell us something about our products.”

Edgerton spoke of several topics along with Upslope Brewing head brewer Sam Scruby.

QUALITY IS JOB NO. 1: Since hitting the 15,000 barrel mark in production, Boulder, Colorado’s Upslope has employed a QA/QC position.

“Quality is everyone’s job and we strive to train and include each department in sensory analysis and training — including off-flavor detection,” Scruby said. “Having consistent procedures and well-trained employees is another focus for maintaining quality across all brands.” (Read more at: Keys for Quality Start in a Brewery’s Lab)

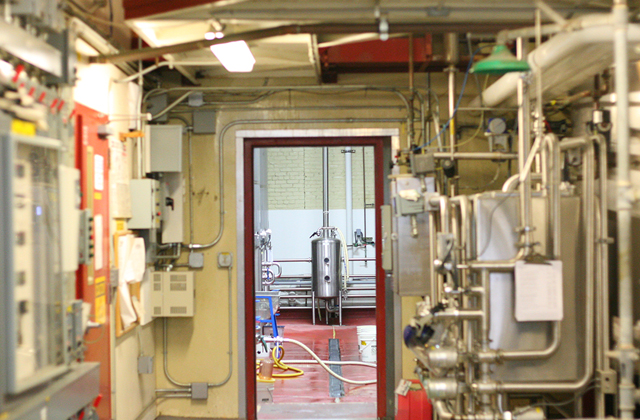

OBSESSIVE BEST PRACTICES: “We constantly analyze, taste, and adjust,” Edgerton said of the work done on beer at BridgePort. “We check all incoming ingredients using our noses, tongues, eyes, all senses. We taste the product at every stage of our process, including for several months following packaging. Cleanliness is ingrained in every employee from day one to make sure that we never send an infected batch out the door. Every batch is analyzed chemically and microbiologically at every step of the process.

“It borders on obsessive, but is truly the key to making quality, consistent beers.”

MAINTENANCE AND IMPROVEMENT: Upslope has retrofitted its canning line to routinely get dissolved oxygen below 30 parts per billion, which is a major step in slowing the aging and staleness that occurs in packaged beers over time, Scruby said.

Yeast management is also a key, he added.

“We rigorously test our yeast prior to every harvest, and re-pitch,” Scruby said. “We have also developed multiple testing points for beers moving through our facility.”

STYLE STUDY: Having a background in the beer, even on an experimental level, can help determine what will be a success with consumers. Setting a standard, not just for one beer but across an entire portfolio can be key.

“Standardization comes from knowing what our beers should taste like and constant monitoring to make sure that we meet those criteria,” Edgerton said. “Once you have the recipe where you want it and your customers like it, you have to make sure that you continue to deliver. It’s not a simple process and it’s never “finished”. But we love making beer and look at producing consistent products as a labor of love.”

CHECK YOUR EGO: Across-the-bar or any in-person interaction is great. You can have some wonderful fans and even win some awards. Don’t let that be the end.

“[Beware of] getting a big head when people tell you that you make the best beer on the planet,” Edgerton said. “You have to graciously accept the praise while realizing that a lot of other brewers are being told the same thing. Your customer is king so do the right thing: never rest on your laurels and constantly strive to make better beer!”

Photo credits: Upslope Brewing Co. & BridgePort Brewing.

Be the first to comment