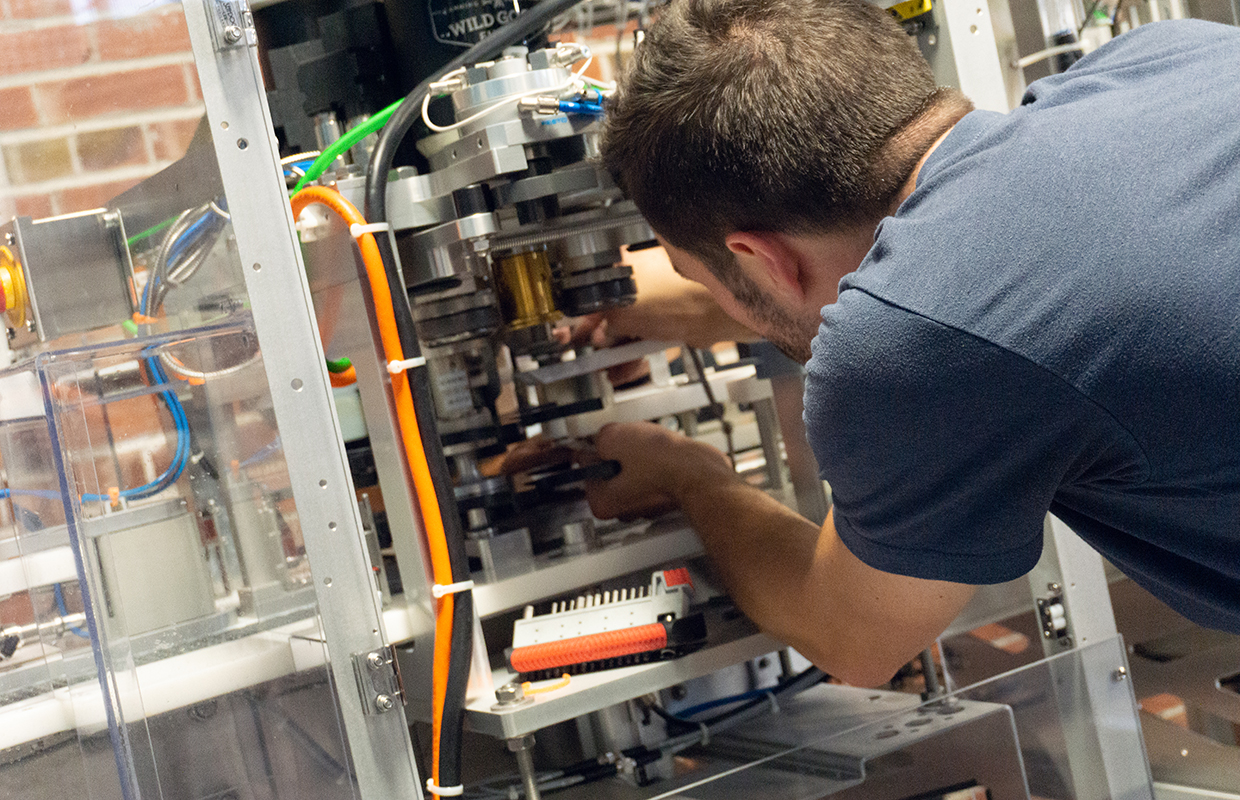

Harris Dunlap has a schedule but isn’t afraid to not stick to it. The Lead Facilities Engineer for Seattle Cider and Two Beers Brewing, Dunlap works to make sure all the equipment at the facility is in tip-top shape, but that means being able to adapt to challenges.

We have never been afraid to make alterations to our equipment to improve our process,” Dunlap said. “There are a whole host of things that are essential to quality production operations. I am sure you are thinking of several right now and you are probably right about their impact and how undervalued they may be.”

Scheduled preventative maintenance seems to be at the top of the list of things that get the ax when last-minute changes are made, Dunlap pointed out. However, what is truly overlooked are process improvements and modifications.

“When equipment does not work the way we would like, we make every effort, within reason, to change that,” he said. “Too often inefficiencies are tolerated because equipment is functioning ‘as designed.’

“When your equipment, processes, and personnel all work together in concert, morale, efficiency, creativity, and quality all improve.”

Dunlap said that the data they have compiled has shown that PM is essential to maintain equipment efficiency above 60% and that the number of unplanned maintenance calls doubles if something like the facilities’ cartoners doesn’t get a monthly spa day two months in a row.

“This way of thinking has led us to design and manufacture custom parts for machines before we have even commissioned them,” Dunlap said, noting that there have been long phone calls with Controls Engineers to change the way sensor data is interpreted because a valve stays open too long, and countless months of tinkering.

READ MORE: These Maintenance Checks Could Save Money, Downtime

“Be cautious, deliberate, and thoughtful about any changes you make to your equipment or processes,” they said. “But do not accept things because ‘that’s just the way they are.’ “

Dunlap uses Airtable for scheduling and documentation.

“[It] functions as a big spreadsheet,” Dunlap said. ”I have sections for recording information about our equipment and facility infrastructure, managing projects, and scheduling maintenance. These larger sections are then all broken into subsections, and they link between each other.

”This way, if I look up our WG800 I can see notes about the equipment (bearing sizes for the seamer motor, part numbers for wear items, maintenance manuals, etc.), I can review previous scheduled and unplanned maintenance, and can see notes about related projects (such as custom parts that I have designed or notes on the canning line build-out/commissioning.”

Dunlap said the platform is highly customizable and intuitive to use, which is why they chose this route over other options.

”Our facility has grown and evolved over the years, and I needed a platform that is organized enough to make things easy to navigate but also can handle logging the rat’s nest of utility infrastructure from our early days,” Dunlap added.

Saying, ‘the most important work for the year is always the most planned for,’ Dunlap laid out for Brewer some notes on what gets looked at when and how the brewery and cidery works on what things. Weekly, monthly, yearly maintenance follows a hierarchy of consequence and complexity.

- Many of the weekly tasks fall under the Brewers’, Cider Makers’, and Operators’ SOPs: These are typically lower in consequence and complexity: cleaning equipment at the end of a shift, sanitation procedures, quality checks, and such.

- Monthly maintenance typically involves partial disassembly of certain machine components, deeper cleaning, and lubrication, more entailed quality checks. ”These tasks are more important to complete as the consequences are generally higher,” Dunlap said.

- Yearly planned maintenance typically involves machine tear-downs, work on larger utility systems, building inspections, and more. “These tasks can take multiple days to complete, are sometimes highly complex, and are essential to the quality and efficiency of our facility,” Dunlap added.

Photo courtesy Christina Dean, Two Beers/Seattle Cider

Be the first to comment