Pure Project Brewing’s latest collaboration release, Cloud Pleaser, is more than just a hazy IPA with bright notes of mango, lime, and nectarine. This release, which debuted on September 4, showcases how breweries can utilize technology upgrades to enhance sustainability while enhancing the quality of the beer itself.

The San Diego brewery collaborated with Ambitious Ales and its Australian technology partner, Frigid.Cloud, to create the beer, but the real insights come from the last year the Southern California company spent testing and integrating Frigid.Cloud’s system into its Vista production facility.

Co-founder and brewer Winslow Sawyer said the brewery held off on any release tied to the partnership until it had enough data to prove the system’s impact.

“We wanted to be able to quantify the success of the technology through different brewing seasons, so we could confidently communicate its effect,” he said.

Collaborations have long been part of craft beer’s playbook, but Sawyer sees them as more than just a chance to share recipes and market to each other’s fans. He believes they are an opportunity to communicate bigger lessons.

“Because brewing will never have zero impact on our environment, we are consistently working towards making our process as sustainable as possible,” he said. “From a marketing perspective, these collaborations allow us to introduce ourselves to new customers and share our successes. We feel it’s important to communicate our trials and success stories with our peers and customers to fulfill the promise that ‘Beer for Good’ embodies.”

That perspective turned Cloud Pleaser into both a product release and an educational piece, putting sustainability in the spotlight alongside delicious hop characteristics.

The decision to partner with Frigid.Cloud wasn’t automatic. Sawyer admitted he is cautious about adopting technology in the brewhouse, especially when it arrives with lofty claims.

“I’m often skeptical of new whiz-bang tech that promises the world,” he said. “We wanted to test and confirm that it worked with our processes and had the capabilities that were pitched to us.” The fact that Pure Project waited through a full year of brewing conditions before attaching its name to the release is telling. It shows diligence along with an awareness that the industry can be filled with tools that sound good on paper, but struggle to live up to the hype in everyday situations.

In this case, the software exceeded expectations, he said.

“Frigid.Cloud met all of their claims, and they were amazing to work with,” Sawyer said. “Not only customizing the system to our processes and brewery, but being all around good blokes.”

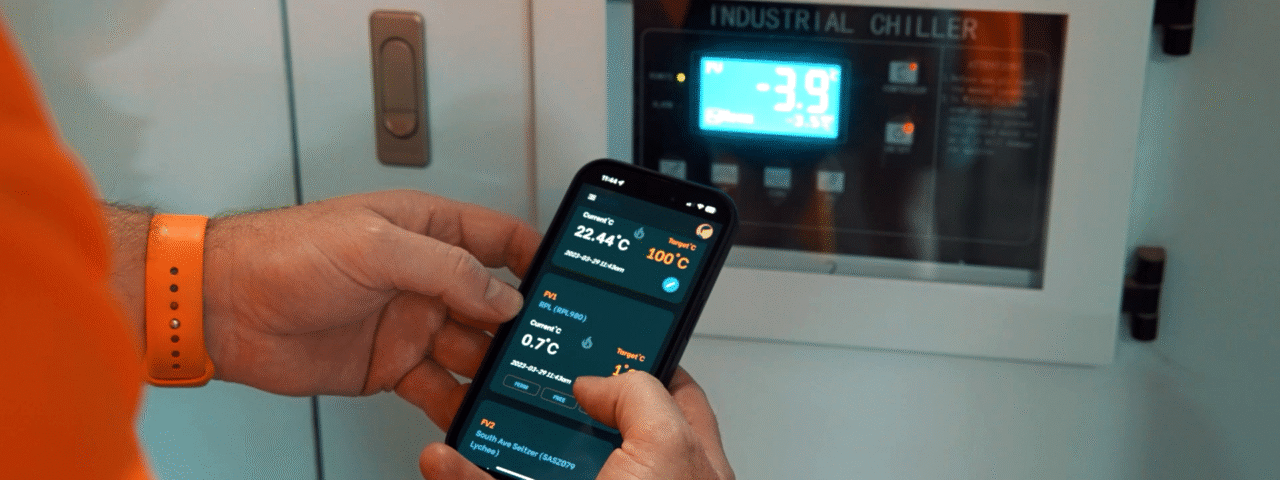

That adaptability mattered because the Vista production facility wasn’t built with high-tech automation in mind. The system worked by wiring Pure Project’s existing valves, probes, and relays into networking hardware supplied by Frigid.Cloud. Automation can often be seen as disruptive or expensive, but Sawyer’s team was able to incorporate it without halting production.

The most visible savings came from the glycol chiller, historically the brewery’s biggest draw on electricity. By introducing features like pulse cooling (pushing glycol through tank jackets in intervals rather than running constantly) Pure Project reduced the load on its system. Scheduling cold crashes overnight, when ambient temperatures allowed compressors to run more efficiently, further lowered demand. Even small adjustments to chiller set points during peak hours helped the brewery chip away at wasted energy. Those changes added up to tens of thousands of kilowatt-hours saved each year.

The operational impacts reached further than electricity bills. Remote monitoring and control have changed how the team manages fermentation and scheduling.

“Being able to schedule and remotely cold crash a tank on a weekend without coming in is amazing,” Sawyer said. The same tools allow Pure Project to power down its electric hot liquor tanks for the entire weekend, only bringing them back online on Sunday night so they’re ready for Monday brewing. That small change reduces energy use while making production schedules more predictable.

The shift has created a new rhythm at the brewery, where brewers are spending less time managing equipment and more time focusing on the beer itself. Data logging fermentation curves has also given the team clearer insights into when to make process adjustments. Those operational benefits are difficult to quantify, he noted, but for a brewery navigating growth across multiple taprooms, the efficiency gains may be just as valuable as the utility savings.

The collaboration with Ambitious Ales and the release of Cloud Pleaser gave Pure Project a chance to share the results with customers and peers. Sawyer sees that educational component as essential.

“From a marketing perspective, these collaborations allow us to introduce ourselves to new customers and share our successes,” he said. “We feel it’s important to communicate our trials and success stories with our peers and customers to fulfill the promise that ‘Beer for Good’ embodies.”

READ MORE: Despite Urban Setting, Sketchbook Builds on Sustainability Goals

Sawyer’s advice is to start by auditing utility use and process timing before jumping into bigger investments.

“Some sustainability wins can be about more than saving the planet; they can also help the bottom line of your business,” he said.

If electricity bills are climbing, he recommends exploring technology solutions, especially for breweries already working with solar.

Cloud Pleaser may capture attention for its taste, but it can represent even more. Sustainability doesn’t always require sweeping overhauls or massive budgets. Sometimes it comes down to smarter timing, better monitoring, and a willingness to test whether new tools can actually deliver.

Be the first to comment