In designing a canning line, the KISS Method (Keep It Simple Stupid) can be applied, especially when you keep in mind how much cleaning is involved.

“The harder it is to clean, the less likely people are to do it,” said Baxter Brewing’s Merritt Waldron — whose book Quality Labs for Small Brewers: Building a Foundation for Great Beer is now available.

So making that cleanup easier by having a well-designed canning line can be a great key to quality and efficiency.

Waldron said to try to have your line as close to the brite tank as you can.

“The less hose you have between the brite and your canning line the better,” he said. “If you have trench drains nearby, that’s even better for cleaning, just making sure that everything is easy to clean.”

Waldron also said to consider having CO2 and air depending on your line.

“Most lines use both CO2 and airdrops, so you need to make sure that you have enough supplied,” he said. “Those are usually pretty easy to run in a brewery, pretty small and a lot of people just use flex hose for CO2.”

To help with workflow and to help avoid accidents, Waldron suggested making sure that the area has access and that it doesn’t block operators trying to run the line or pack off.

“Consider the agronomics,” he said. “Because if you have to keep stepping over hose — that sucks. It adds more trip hazards, which could be a safety issue.”

Canning days can be long, tedious work. So making the canning line as comfortable to work on as you can is a great way to help employees that are doing it.

“It’s not always perfect,” Waldron said, mentioning that Baxter even has a line in their process that workers need to step over.

“But other than that, we try to be as comfortable as we can behind that line,” he said. “Because we’re standing there long hours at 14 plus hours a day between two shifts.”

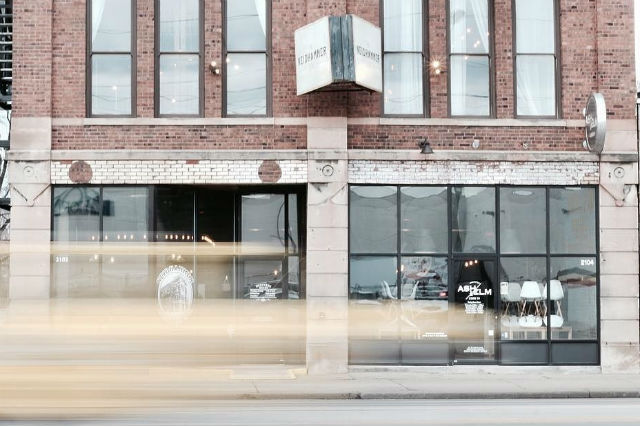

Photo courtesy Urban Artifact

Be the first to comment