In our line of questioning for the recent 2022 Expert Outlook articles, breweries from across the country shared how they have worked in looking for local suppliers — be that for food or ingredient supplies, manufacturing help, or knowing that they are a local supplier themselves and how they can help their communities in a multitude of ways.

The most shocking change for Bootstrap Brewing co-owner Leslie Kaczeus was price increases experienced across the board on all components that went into making, packaging and shipping beer.

“Starting with the ‘Candemic,’ our contracted supplies got cut because there was not enough worldwide capacity and our prices immediately increased 21%. We had to hustle and source additional cans from three different suppliers both locally and internationally and those cans were double and triple the cost we were expecting,” she said, noting that the Longmont, Colorado brewery looks to work locally as much as possible.

“Obtaining cans is a challenge but we have local can suppliers who we work with closely to fill in the gaps for us,” she said. “We also try to buy equipment locally so that we have immediate onsite support if required. At this point local relationships are critical and in some cases help you get what you need when you need it.

“Keeping local also has the advantage of lower freight costs and customer service that’s located in our same time zone.”

The more DuClaw invests directly in its community, the more the local business ecosystem will thrive as a whole, pointed out Rachel Bradley, the brewery’s Marketing Manager.

The Baltimore mainstay has worked with a local family-run woodworking company, Mark Supkik & Co, since the 90s.

“They’ve been making our tap handles, and they always do a great job,” Bradley said. “We also work with food supplier Araza Purees and label maker, Bizerba Gamse. From a business standpoint, it’s reassuring to know we can rely on their customer service and production teams.”

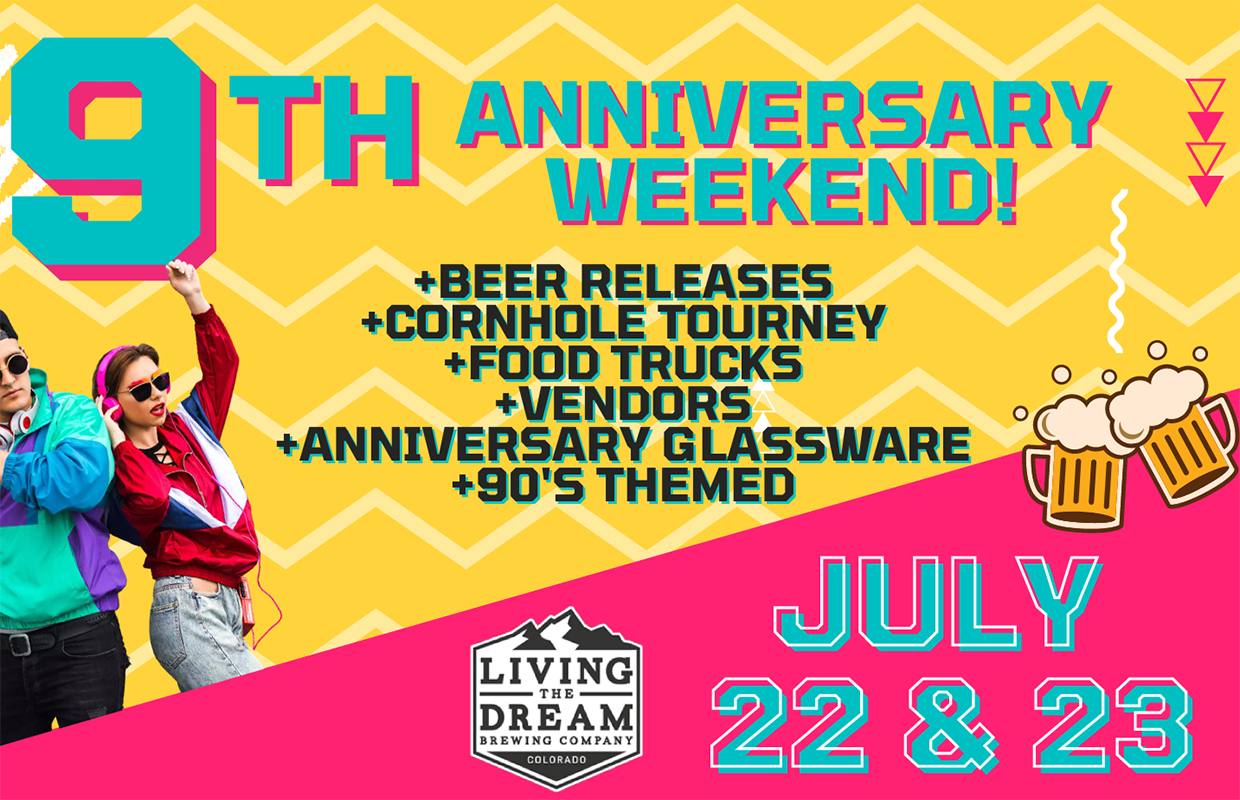

Living the Dream Brewing‘s Jason Bell believes that as one of those local suppliers to its customers, it is very important for them to work locally when possible.

READ MORE: Finding Ways to Tie A Brewery Into A Community

“We have been fortunate enough to form partnerships with some great small companies in our area,” Bell said. “Also, as many larger suppliers have issues with their supply chains, it’s caused us to seek out alternative, local suppliers for the goods we need.”

The Lone Tree community has supported the brewery in its journey and Sales & Marketing Director Dennis Stack said they want to support them in any way they can.

”We opt for local options when available and love working with local suppliers,” he said. “Working with local businesses also gives us the ability to get to know the people behind the business and who we are supporting.

”Typically, the investment is returned in a multitude of avenues, and that is always appreciated.”

Collaboration with local businesses is a key part of 42 North’s DNA.

”It is built into our brewery’s mission statement,” said founder John Cimperman. ”We go out of our way to collaborate with not-for-profits, as well as like-minded brands. Our collaborations go beyond beer and include partnerships with local retailers, bakeries, coffee shops, and ski resorts.

”In addition to doing good, these collaborations help create brand ambassadors for the brewery. it’s truly a differentiator and a ‘win-win’.”

Temperance Beer founder Josh Gilbert said they always strive to partner with local businesses in the Evanston, Illinois area where they can.

”Our taproom is a great place to do that with food, snacks, bottled water — anything,” he said. “We also use local coffee in brews, brew a beer for a celebrated local market, send spent grains to a nationally-known local bakery, and partner with a hometown meat and charcuterie shop on their beer brats (their number one seller!).

”Not only do these partnerships strengthen our local economy, but they also allow us to promote and celebrate fellow local small businesses. And have a lot of fun!”

Be the first to comment