For spouses Jenn and Dan Peterson and their brewery, Ferment Brewing Company out of Hood River, Oregon, one part of releasing two experimental beers on May 8 as part of a quarterly lineup of 16-ounce cans during COVID-19 meant adopting a new sales strategy.

The plan was to have a live launch initially for Top Ferment Bright West and Bottom Ferment Kaleidoscope and then self distribute locally in 16-ounce four-packs. Now, the brewery is simply operating through its takeout window.

The IPA and Kellerbier are both styles that Dan has been experimenting with for a while.

“I’ve been playing around with doing a cool whirlpool hop edition, with hops going into the kettle during the boil, and so it’s kind of an old-school Northwest/West Coast IPA,” Dan said.

“I’ve also borrowed those techniques and more modern Northeast/New England Style IPA and really trying to keep the bitterness down but still letting tons of hop aroma into the beer.”

For Kaleidoscope, Ferment’s first Kellerbier, “it’s one that sort of swaps roles, where the trend for IPAs has been to get Hazy and big on dry hops, so for the Kellerbier, in this case, we dry hopped it with Loral hops, a newer Northwest variety of hops, and then also Crystal, which is an older Northwest variety and one of my favorites,” Dan added.

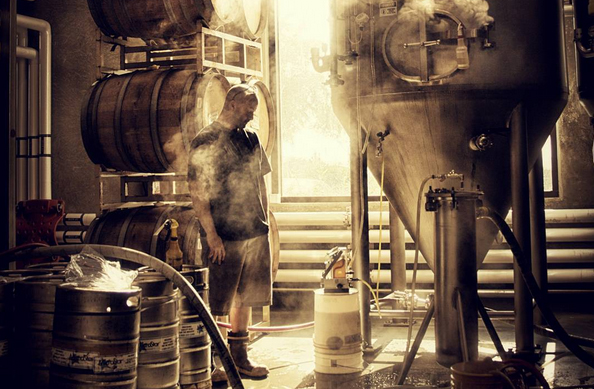

The staff is operating on a small, core team right now, and Jenn noted that the brewery’s voice is more personal than ever, with a smaller staff working on social media and marketing.

“It’s really clear that people are making intentional choices to support the brands they care about, and we feel it,” Jenn said. She added that the plan was to launch the can line a little earlier, but it was put on hold when the pandemic hit the US. Finally, they decided to go for it and actually brew the batches of beer and schedule the canning.

As soon as the two experimental beers went into cans, they sold out quickly, with a lot of support from the community. The brewery also includes a kitchen, and making alterations to the menu happened soon after the restaurant had to shut down. It’s also meant doing a lot more work by hand in the kitchen, instead of relying on equipment.

More than 50% of the sales pre-pandemic were keg sales. Now that focus has shifted to packaged sales.

“In the brewhouse, we’ve definitely analyzed efficiencies and improved wherever possible,” Jenn said.

“We’re much more focused on packaged product,” Dan said. “We were selling a lot of kegs before, and now we’ve definitely shifted gears toward being a production brewery. It’s kind of a week by week, figuring out what and where we need to be focusing our attention.”

It was only a month before the state of Oregon ordered closures of taprooms that the brewery installed a crowler machine which Jenn called a “godsend” during this time where the brewery can only sell to-go orders.

Be the first to comment