Although Wilmington Brewing‘s brew schedule hasn’t changed much, the North Carolina facility’s packaging has moved to almost all cans currently, a large departure from before the pandemic, said co-founder Michelle Savard.

“We used to keg a lot, but with restaurants and draft accounts closed or somewhat open, our cans have really saved us,” she told Brewer.

Sales of the brewery’s most popular beer, Tropical Lightning IPA, have increased especially with 16-ounce cans in 4-packs to-go.

“I think most people right now are going towards more established brands and Tropical Lightning is a Wilmington favorite, so it’s easy to order when you know what’s good,” Savard said. “We are still having decent sales with new releases, especially our IPAs. We also launched a new 12oz 6-pack line of lighter sessionable beers that have been doing really well.”

The switch to more cans was actually a plan in the works for Rowley Farmhouse Ales this year, which timed out great for the Santa Fe, New Mexico brewery.

“We already had some deals in place in regards to cans,” explained head brewer Wes Burbank. Although cans were set, everything else — such as labels, lids, and other ancillary pieces for canning — has been pretty tricky to set up to get logistically.

“We are just trying to stay far ahead on ordering lids and labels to compensate for the slow turnaround since that’s basically what every brewery is doing at the moment,” Burbank said.

The brewery chose to buy its own canner because canning companies wouldn’t work with the sour facility.

“I don’t blame them for not wanting to take the risk,” Burbank said. “We opted for a machine that can be easily cleaned and steamed through all beer-touching parts before and after each shift to ensure our few clean beers stay clean.

“We also opted for distribution because we were already doing it with kegs anyway, and even pre-COVID, we just don’t see big lines on the days that we release beers, as our whole state has the population of some of the cities that a lot of more popular breweries are in.”

In Charlotte, Divine Barrel started doing can releases every two and a half weeks, where previously Managing Partner Gavin Toth said the brewery was only doing them about once a month.

”Each release, we are typically pushing out three new beers, and our brew schedule has gone a little crazy as of late,” he said. ”We are making a lot more beer to can, so our kegs are just sitting empty.

”While that makes life a little easier, it is sad to see all of the kegs just sitting there. We will continue to can as much beer as possible, and we are currently starting to keg off a little more beer each time.”

Wilmington closed its taproom for the time being and Savard said they are ’canning like crazy.’

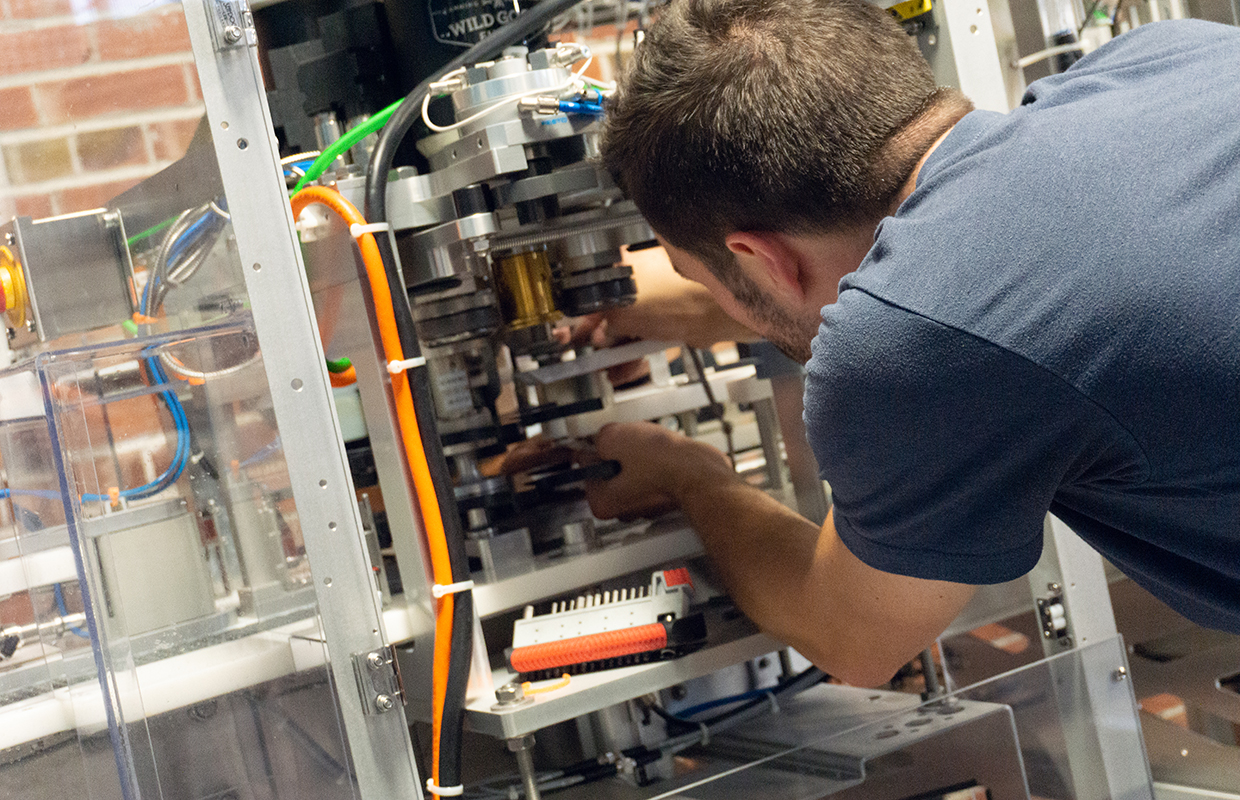

“We are grateful to have our own Wild Goose 5-head filler canning line here in the brewery,” she said. ”We have certainly distributed more and gone online a bit through Tavour.”

Burbank says he does see some challenges ahead in regards to trying to find a balance between keeping certain draft accounts and filling cans.

”We’re a tiny brewery, so fermentation and storage space is the biggest concern at the moment,” he said.

Be the first to comment