Nitro carbing a brand can add a great mouthfeel to a product, but regardless of style, it can be a hassle.

“[It] often requires a decent amount of extra equipment,” noted Dorchester Brewing Head Brewer Andy Johnson about adding nitro to brite tanks. “We use an in-line nitro infuser which fixes a lot of the conventional headaches of nitro.”

As the beer moves from a low carbed keg to the tapline, Johnson said they will force beer gas into it to get the product they want.

“This is a nice solution for getting nitro beer on draft in smaller breweries and taprooms,” he said, noting that the Boston-area brewery likes to serve up nitro products in its taproom.

With the in-line infuser set up, Johnson said they avoid any significant process changes when compared to a normal draft line.

“We of course still do the classic nitro pour technique,” he said. “But outside of that, the beer is treated like any other by our front-of-house staff. The only major difference is to keg the beer around 1.5 volumes of CO2 which is quite flat compared to most beers.”

On the brewery’s pilot system the Dorchester crew will always allow for two days of rest before packaging as these beers are not centrifuged.

“This allows us to dump any particulates that could have gotten through during the transfer,” Johnson said. “The small amount of pressure that the beer sits under during this rest is enough to reach our 1.5 target CO2 volumes.

Making sure the beer never has high oxygen will help keep your nitrogenating process to stay within specifications.

READ MORE: A Look Behind Firestone Walker’s First Nitro Canned Product

Topa Topa has found that nitrogenating while maintaining a higher head pressure quickens the process, ”but your mileage may vary,” said Graham Strong, Senior Brewer in a recent Brewer article. Using nitro in place of CO2 in these instances can help alleviate potential cost differences that your brewery may encounter should the ability to get the proper amount of bulk CO2 at this time can be a detriment.

When it comes to packaging, Independence Brewing worked with a special widget can for its Up and Down Brazil Coffee Blonde, using the same technology that is used in canned nitro coffee.

The brewery touted that it was one of only a few breweries in the country to use the patented cans, and among the very first to experiment with canning a nitrogenated coffee beer.

The logistics of canning the widget cans compared to a normal canning day is a little different, though not drastically, pointed out Operations Manager David Hinkle in a recent interview with Brewer.

“One thing we’ve noticed is that yield per batch is lower because of the large amount of coffee we’re putting in the beer — 180 pounds per 60-barrel batch,” he explained. “Then the widget itself takes up space in the can, so a 12 ounce can have more like 11 ounces of beer in it.

“We also nitrogenate in the tank as opposed to carbing, so the uncarbonated beer has no foam, which increases fill times and slows the process down, especially since the beer needs to be kept still throughout the process.”

There are also safety issues with the dosing because it has to be just right so that you don’t have exploding beers. That means a word of caution for breweries looking into canning nitro beer.

“Honestly we’d say don’t try this unless you have the time and money to get it right and you have a beer style that demands a nitro can,” Hinkle said. “We felt that the beer we were trying to make could only work if it was full nitro, otherwise the coffee flavor would degrade pretty quickly and wouldn’t have dark roasted malts to mask it.

“It was all worth it in the end though, the beer is amazing and the coffee flavor is incredibly fresh and stable. We couldn’t be happier.”

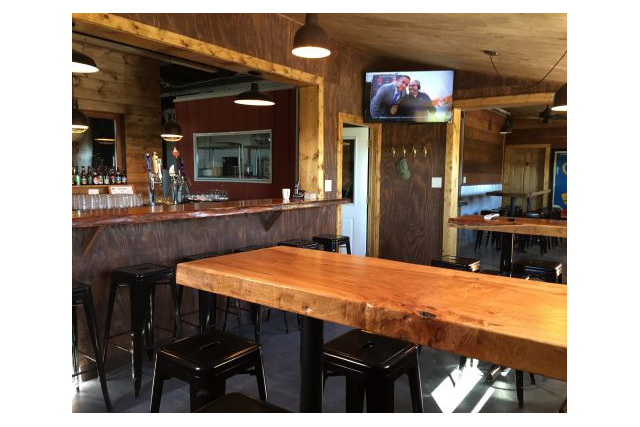

Photo courtesy Dorchester Brewing

Be the first to comment