As more craft brewers start a barrel program, the use of dry steam is becoming a more common solution for sanitation. It’s also welcoming news that awareness of general brewery sanitation is on the rise. For those who haven’t had the opportunity to learn about the benefits of dry steam for breweries, Steamericas has prepared a list of the most frequently asked questions on steam.

Q: How is dry steam used in breweries other than for swelling barrels?

Having a barrel program naturally brings about at least two additional challenges: rehydrating and preserving costly barrels and sanitizing them properly upon each use. The importance of sanitizing barrels is paramount, especially if wild yeast strains or food ingredients have been introduced. Dry steam is widely used as a natural sanitizer in the food processing and winery industries. High temperature delivered by steam is what kills microorganisms. Unlike water-based methods (including ozone), dry steam — a form of gas — can travel through pores and reach above 80C a few millimeters beneath barrel surface in minutes. Brewers also love that the Optima Steamer can rehydrate barrels while sanitizing in a fraction of time and water (three minutes, ¼ gallon for a 60-gallon barrel for example) instead of using 60 gallons of water and waiting overnight.

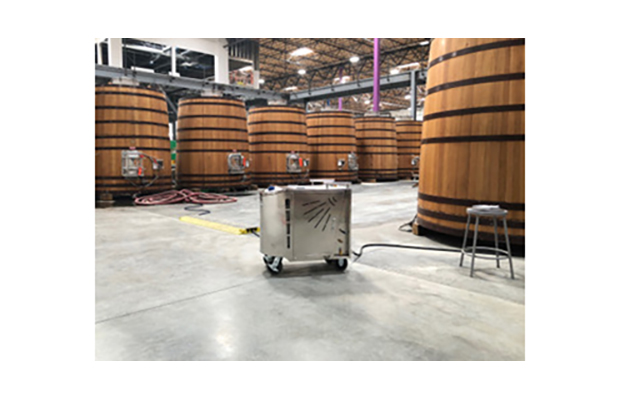

In addition to barrel applications, steam is used for sanitizing foeders, fermenters, tanks, bottling lines, floors, drains, cool ships, chiller coils, kegs, and more.

Q: Can I hook up the steam barrel wand tool to my boiler?

Dry steam cleaners such as the Optima Steamer generate saturated steam. Saturated steam is when water has boiled at 212 degrees Fahrenheit and become a form of gas.

For example, the Optima Steamer generates saturated and superheated steam in the steam boiler at 125 psi and 350 degrees Fahrenheit. A typical boiler generates what we consider wet steam. Wet steam behaves like liquid. Because the barrel tool was specifically designed for dry steam generators with a certain flow rate, it would be difficult to emulate the same results used with a boiler or another dry steamer with less flow rate.

Q: What temperature should I reach to properly sanitize barrels, foeders and tanks?

160-180 degrees Fahrenheit is known to be the sanitizing temperature. Certain yeast strains requires a higher temperature to be eliminated. Wild yeasts such as Brettanomyces grow deep in wood, and the temperature must be reached where the microorganisms hibernate (e.g. 2-5 mm beneath wood).

Q: What are the requirements to run a commercial steam cleaner?

For electric units, you must have three-phase power or single-phase high-voltage power such as 208V and above. The Optima Steamer is also available with a diesel/kerosene burner with minimal, clear exhaust.

Q: What specifications and factors should I consider when purchasing a steamer?

- Steam capacity rate and output: To compare steamers, look for the steam capacity (or production) rate. This shows how much water the steamer is capable of turning into dry steam per hour.

- Boiler size: Another way to gauge the performance of a steamer is finding out its boiler size. If the steamer has a small boiler, you will run out of steam very quickly and have to wait for steam to replenish after few minutes of use.

Water tank size and direct hose hook-up availability: If the steamer has a small water tank, this means you have to refill it often. True commercial grade steamers often come with a direct water-line hook-up so that you never have to refill the water tank manually. - Hose length: Because steam is a form of gas, it cannot travel as far as water (liquid) can, which limits the length of the hose. If you have a commercial-industrial grade steamer, you can somewhat overcome the hose length restriction thanks to its abundant steam flow and pressure.

- Parts and service availability: Is there a service center within driving distance? If you are to self-service, how quickly can you get parts delivered, and can you afford downtime?

- Soft water: Commercial steamer or not, steamers require soft water, period. If you have hard water in the area, add in the cost of a soft water system into your budget. Dry steamers have a pressurized vessel. Anything other than pure H2O stays behind in the steamer system and will become an issue if you don’t treat the water.

1 Trackback / Pingback