In most cases, waiting to purchase a canning line for your cidery comes at a point when the volume is at a certain level, and the ability to sell those cans to retail becomes apparent.

It was a little different for Busky Cider.

“(The pandemic) forced us to pivot in virtually every aspect of our business and one of those pivots was moving our focus away from a single dominant flagship to lots of smaller batches,” explained Busky’s Will Correll.

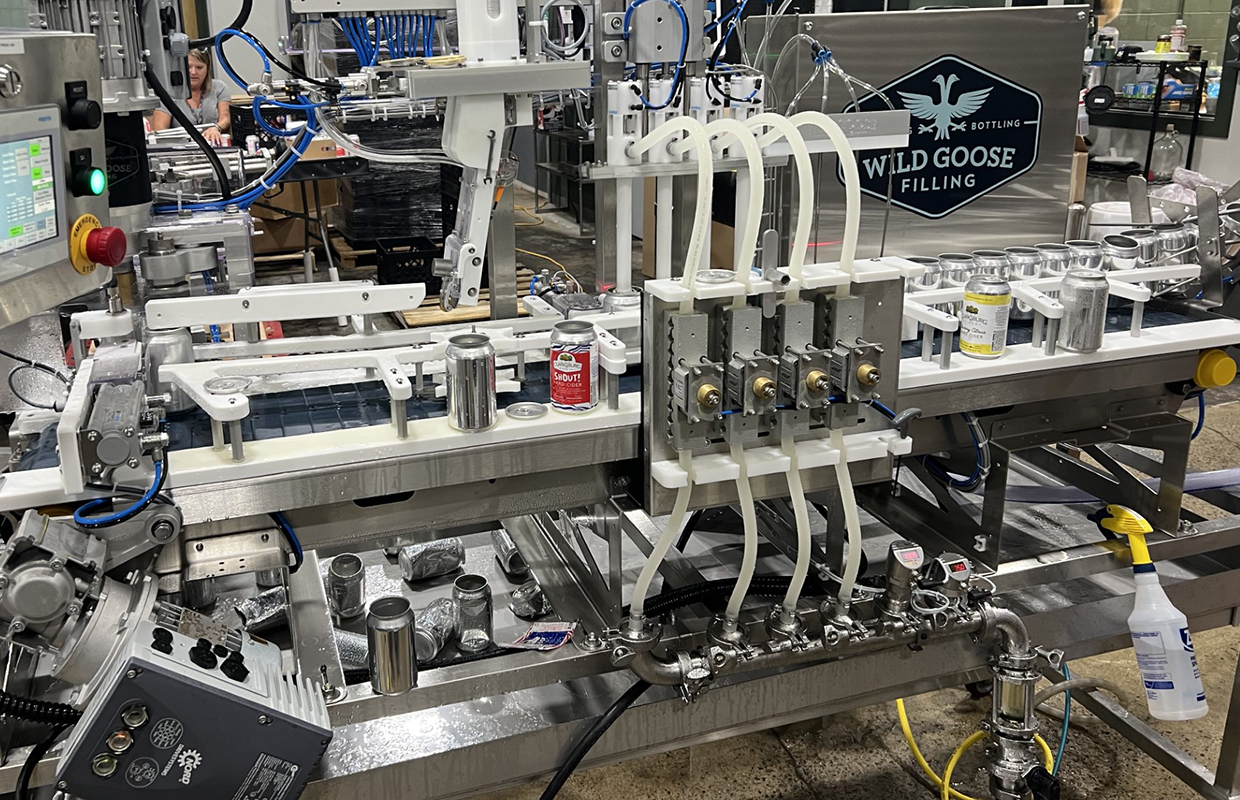

The cidery mobile canned for the first five years of business, but purchased a Twin Monkey unit a couple of years ago.

“Ironheart Mobile Canning (formerly Old Dominion Mobile Canning) does a great job and we did not switch away from them because we were unhappy with their service,” Correll said. “I would imagine most people assume, and in many cases, it will be true, that companies buy a canning line because they have grown their volume of sales enough to justify the equipment and training investment.”

But with the pivot to having their own canning line on-site at all times, Busky instead started to make smaller batches of product and the need to be scheduled more dynamically and quickly while waiting for mobile canning availability was causing scheduling issues.

Busky purchased a canning line that ran slower than the mobile canning unit they had been using, but Correl said it also had a lot more automation and has allowed the company to cut down on labor, and speed up on scheduling runs.

“And (it) obviously put the mobile canning savings towards paying off the equipment,” he said. “(That) doesn’t hurt either.”

READ MORE: Cider Corner: More Reasons to Consider Low ABV Options

After opening a new facility, Arizona’s Cider Corps was fortunate to have the room and experience to have its own line, which has helped shape a much better canning day after learning from trials and tribulations from the original location.

“That allowed us to improve our layout at our new production facility,” said Production Manager, Blake Somsen. “When Jason (Duren, Cider Corps co-owner and cidermaker) and I were talking through the design, we wanted to make sure we had sufficient space to get pallets of cans both in and out of the facility without trapping ourselves with lines and equipment.

“On the other hand, we wanted the tanks to be as close as possible to the canning line to ensure the shortest distance and minimize breakout.”

Cider Corps decided on an open workspace in the middle of its operation that has three entrances and exits, each wide enough for a pallet to pass through easily.

“We now load on one side of the line, run our tank and drain lines through the middle, and stack cases onto pallets on the far side,” Somsen said. “After, the palletized cases are quickly wheeled away into storage.”

Clarksburg Cider has its own line as well and because of space constraints, is still working on a permanent solution, said Cidermaker Eddie Graves.

”The canning line is stored against a wall when it is not in use,” he told Brewer. ”The day before canning, we put the line and depalletizer in front of the tank.”

Because Clarksburg packages cider with residual sugar, it can cause cans to ’grenade’ without some intervention, Graves said. To avoid this, after the cans leave the canning line, they go through a pasteurization process, he explained.

”The process consists of the cans being Paktech-ed, then placed in milk crates and submerged into our ’hot tubs,’” Graves said. “After a nice soak in the hot tub, they get cased, palletized, and let naturally cool down.”

A key to putting the canning line out each time is it must be positioned to not impede pallet traffic between the line and two batch pasteurizers.

Be the first to comment