Just as brewers pour their vision and effort into creating unique brews that will stand out, Cholaca has always looked for the best solutions to their clients’ needs, resulting in their one-of-a-kind liquid cacao for brewing.

But for years, maintaining the highest quality product meant that Cholaca liquid cacao was only available in refrigerated packaging. While this ensured freshness, it also posed challenges in terms of shipping and storage, particularly for smaller brewers.

Cholaca recognized the need to make their product more accessible and convenient without compromising on quality. Now the same incredible liquid cacao product is available in aseptic bag-in-box packaging, making it even easier and more affordable to use.

Finding the technology to fit the vision

Cholaca long wanted to make it easier to ship and store their liquid cacao by using aseptic packaging, but it took years for the technology to catch up to their vision.

Aseptic technology has revolutionized the food industry by offering a pathway to provide safe foods to more people and places than ever before. It involves three key components: sterilization of the product, sterilization of the packaging, and maintaining that sterility during transfer. The result is a range of shelf-stable products that can be stored and shipped without the need for refrigeration.

Heat-treating products to make them shelf-stable is part of this process, and has been around since the early 1800s. Canned foods — whether canned at home or in an industrial process — use heat and pressure to preserve foods. And in the 1960s, Tetra Pak pioneered a high-temperature process combined with aseptic packaging to create shelf-stable milk and other products.

Cacao, with its unique characteristics, is radically different from most of the products you find using this amazing technology, which posed problems for the Cholaca team in bringing their liquid cacao to market in aseptic packaging.

Cholaca bagged the answer at last

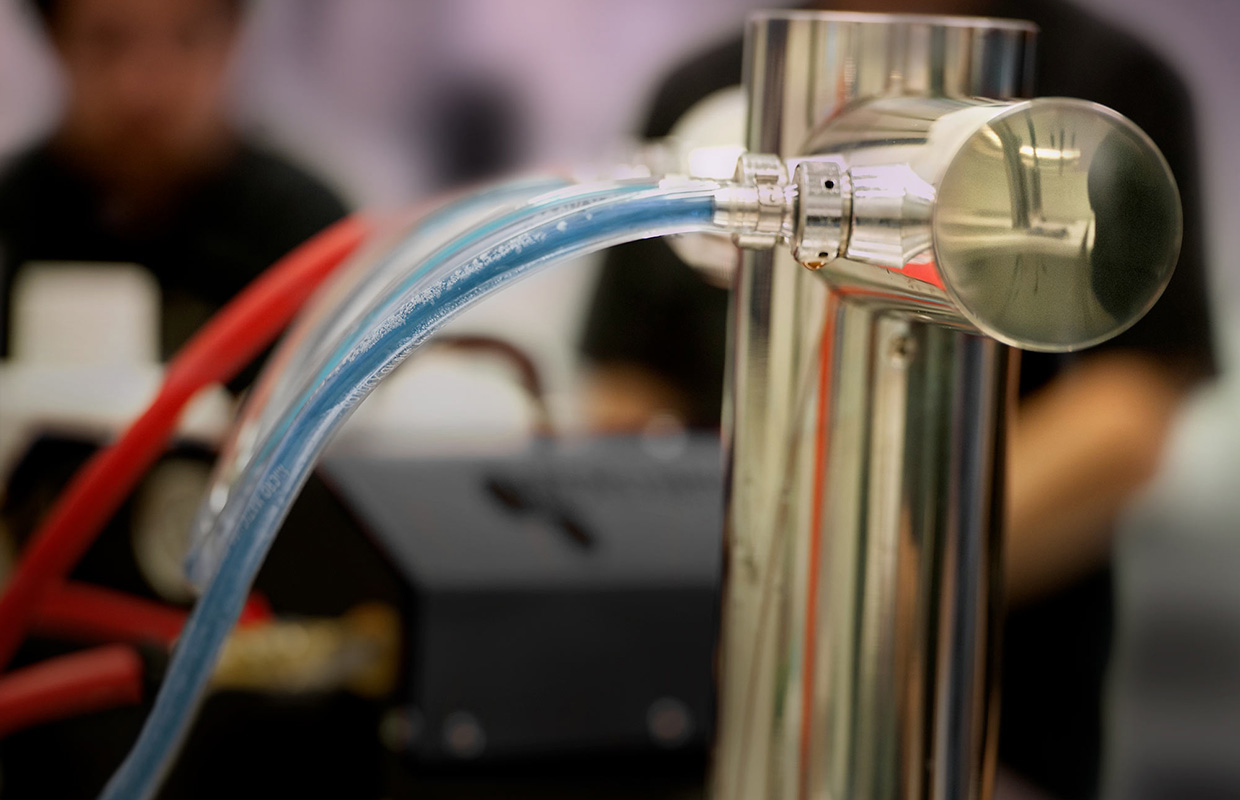

After years of research and testing, Cholaca cracked the code. They found the answer in a combination of Ultra-High Temperature (UHT) processing and a flexible pouch packaging. Similar to the ultra-pasteurization of milk, this method involves briefly heating the product, followed by rapid cooling and packaging. The liquid remains untouched by air throughout the process, eliminating any microbial contamination.

This groundbreaking technology, once only available to large-scale operations, is now accessible at a smaller scale, enabling us to make a shelf-stable product without any additives or modifications.

This leap forward in technology holds great promise for future innovations at Cholaca, including the ability to offer everything from dispensing units to different sizes, variations, and variables of Cholaca’s signature products.

The result: An even better liquid cacao for brewing

Cholaca’s aseptic processing and packaging retains all the health benefits of the liquid cacao, while offering an even more delicious product. The aseptic processing actually enhances the product, making it smoother and creating a better mouthfeel.

Cholaca’s liquid cacao is easier to handle than solids, eliminating the yield loss and mess that occurs when using solid cocoa nibs. Plus, the liquid format allows brewers precise measurement, seamless mixing, and effortless integration. This results in consistent flavor profiles across batches, providing brewers with reliable and repeatable results they can always count on. And there’s less packaging overall, leading to a more environmentally friendly product.

Moreover, Cholaca ensures a premium quality product by controlling the entire supply chain and working closely with their farmers. This commitment to quality and innovation has earned Cholaca their position as a leader in the brewing industry, and demonstrates their commitment to overcome any brewing challenges that arise.

Ready to try liquid cacao in your next brew? Contact Cholaca today and let them help you create your next best seller.

Be the first to comment