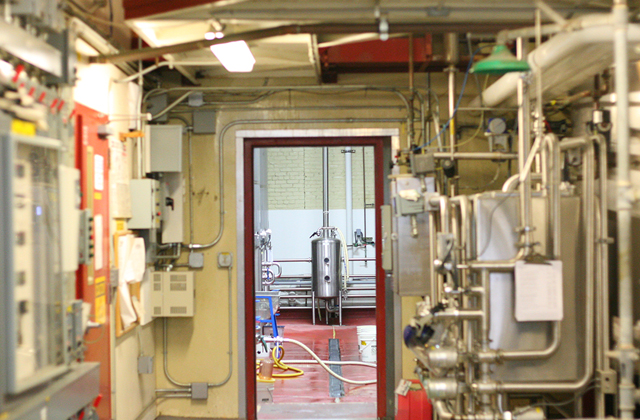

Working to more precisely do the job intended, many breweries look to automation to help in a the brewing process on many levels.

Brewer spoke with Louisville’s Against the Grain about it’s new flow metered keg filler while in Salem, Virginia, Parkway Brewing is upgrading a new bottling line.

For Against the Grain, the addition of the keg filler helps to reduce the likelihood of short and over filled kegs.

“Over-filled kegs can quickly add up to lost output even over a single 30-barrel batch,” said Against the Grain Marketing Manager Katie Molck. “Not to mention the increased loss from slowly bleeding the keg while filling.

“It is much easier from a labor standpoint, there is no training folks on the ‘feel and appearance’ of beer filled foam. It means less loss to filling kegs, which results in more kegs available to our distribution partners.”

Choosing which bottling line would be right for Parkway Brewing was paramount said Lead Brewer Sam Sadovnic.

“The No. 1 thing was getting a longer shelf life and higher quality in bottles,” he explained. “The idea is to drastically reducing oxygen levels in the bottle … that will expand shelf life and help us get a more quality product.

“We are already proud of our quality, but if we can make it even better, that way when people open that bottle, it’s exactly what we put in that bottle.”

To a lesser degree, the bottling line — which is being funding by a grant that was given to the brewery by the Governor’s Agriculture and Forestry Industries Development (AFID) Fund, which Salem will match with local funds — helps reduce waste.

“A newer line with better automation will be able to control fill levels and foaming, which means fewer bottles are wasted and there less chances for spills,” Sadovnic said. “The new one isn’t faster, but it’s more reliable to work with.”

1 Trackback / Pingback