Breweries may take up to several months to brew, finish, and package a keg of beer. The product quality and flavor can be ruined in seconds in an inadequately maintained dispensing system. Failing to properly clean and maintain a system regularly allows the ‘enemies of beer’ to thrive; negatively impacting the quality of the beer served, resulting in lost sales due to dissatisfied customers. Inflated levels of these enemies will affect dispensing performance, thus foam. Periodically cleaning your draft beer lines ensures resale and lower costs while serving “brewery fresh” beer.

‘Enemies of beer’ may include the following:

- Yeast – Results from a tiny amount left from the brewing process, or it may be wild yeast, which floats in the air. It is usually found as a surface growth on components of a beer system exposed to the air, such as faucets, keg couplers, and drains, and appears white or grey.

- Mold – Usually introduced into a beer system through exposure to the air. It is also found as surface growth on components of a dispensing system exposed to the air, such as faucets, keg couplers, and drains, and is usually brown or black.

- Beer Stone – The raw materials, grains, and water used in brewing contain calcium. Oxalic acids or salts are present in hops and created during the process of changing barley into malt. While dispensing at cold temperatures, these ingredients in beer may result in Calcium Oxalate deposits known as beer stone. Beer stone will build up and eventually flake off inside the beer tubing if the system is not maintained correctly. High amounts of beer stone may also harm the taste. These flakes are often grey or brown.

- Bacteria – Bacteria found in beer are not significantly hazardous to human health; however, their effect is noticeable in beer’s appearance, aroma, and taste. The presence of bacteria results in an “off taste” and cloudy appearance that makes beer unappetizing. A beer that tastes sour, vinegar-like, buttery, or smells like rotten eggs may indicate a beer system contaminated with bacteria spoiling the beer.

Brewery Policies for Dispense System Line Cleaning & Maintenance

Breweries know the importance of proper line cleaning and its impact on their products, reputation, and sales. The Brewers Association (BA) joins over 40,000 breweries and home brewers to publish beer line cleaning procedures and maintenance schedules within their quality assurance policies.

Depending on state statutes, these policies are applied and documented by breweries’ distributors or independent contracted service companies. The consensus is it is essential to clean a draft beer dispensing system at least once every two weeks to prevent deposit build-up from the enemies of beer—additionally, ongoing system component maintenance.

The process and chemicals used to clean and maintain the system will also vary with the beer dispensing system’s type and length. The following section will describe the variables to consider when assessing the best cleaning method.

Line Cleaning Chemicals

Use an effective line-cleaning chemical during cleaning lines to attack the enemies of beer. An alkaline (caustic) cleaner with a high PH or an acidic one with a low PH is applied based on the deposit type present.

Alkaline cleaners, applied every two weeks, attack and dissolve organic proteins, carbohydrates, hop resins, and biofilms. They also are very effective in killing mold, bacteria, and yeast. Acid line cleaners, applied every three months, dissolve inorganic mineral-type deposits, commonly referred to as beer stone.

Both caustic and acid line cleaners are hazardous if not handled and used correctly. Always follow the directions printed on the package and strictly adhere to the manufacturer’s recommended concentration levels for safety and cost efficiency.

Brewery-tested and approved line cleaners are available from Micro Matic. The patent-pending formulas feature:

- The latest surfactant, which reduces surface tension, results in fast, easy cleaning.

- Effectiveness in all water conditions

- Low foam formula

ALWAYS wear PPE (personal protective equipment), including eye protection and rubber gloves, while handling line-cleaning chemicals. It is also important to never mix an alkaline solution with an acid solution. Dispense chemicals into the water to prevent spills. Keep chemical bottles on the floor. Place hazard placards warning personnel to avoid the area. Never perform cleaning when customers are present. Have SDS (safety data sheets) available at all times.

Line Cleaning Equipment & Procedures

There are two methods applied to clean draft beer dispensing systems:

- Re-circulating Cleaning – With a constant turbulent flow of cleaning chemicals through beer lines, this is a highly recommended method for all dispensing systems. Re-circulating motorized electric pumps are designed to circulate cleaning chemical/water mixture from an open container through a beer dispensing system. Connectors from the pump and throughout the system allow continuous circulation through the faucet end (shank) into lines to the keg coupler and back to the faucet end. Circulation of multiple lines is possible as long as the cleaning chemical comes in contact with all internal surfaces. BA recommends a 15-minute re-circulation of a clean chemical mixture.

- Pressurized Cleaning – A less efficient and more time-consuming method requires a 20-minute soak of cleaning chemical/water mixture pressurized from a plastic or metal water container into the beer line to the faucet. Removing the coupler from a keg and placing it on the cleaning container provides the pressure required. Often this method is utilized for picnic pumps, direct draw, and short-draw systems of less than twenty feet in length. A hand pump version is a popular choice for home dispensing systems.

Line Cleaning Three-Step Procedure

No matter what type of cleaning equipment you are using, use the three-step cleaning procedure to ensure the lines maintain the integrity of the beer:

- Begin by flushing the beer from the lines with water to neutralize the acidic nature of beer, allowing the alkaline cleaning mixture to perform. And, if a connection is loose, best to have water leaking versus a chemical.

- Next, clean the lines with the appropriate chemical mixture. Allow chemicals to circulate (15-minutes) or soak (20-minutes) in the beer lines. Apply alkaline mixture every two weeks and acid every three months. Always follow the manufacturer’s recommendations on the proper mix ratio, correct temperature, and contact time.

- The final and most critical step is to flush the chemical from the lines with water thoroughly. Test rinse water with a PH tester or litmus paper to ensure the chemical is no longer present in the system. Reconnect the kegs, dispense beer through lines to the faucet, purging rinse water from the system. Never rinse a chemical mixture from lines with beer!

Maintaining System Components

It is essential that not only should the beer lines be cleaned at least every fourteen days, but on the same level, so should the keg couplers, faucets, and other components. These components exist in aerobic environments where yeast and mold deposits accumulate rapidly – eventually causing quality issues. Brush or wipe yeast and mold residue from exterior surfaces of couplers, nearby tubing, and walls. Remove and disassemble faucets. Then soak in chemical/water mixture, rinse, then brush clean. Reinstall after assembling.

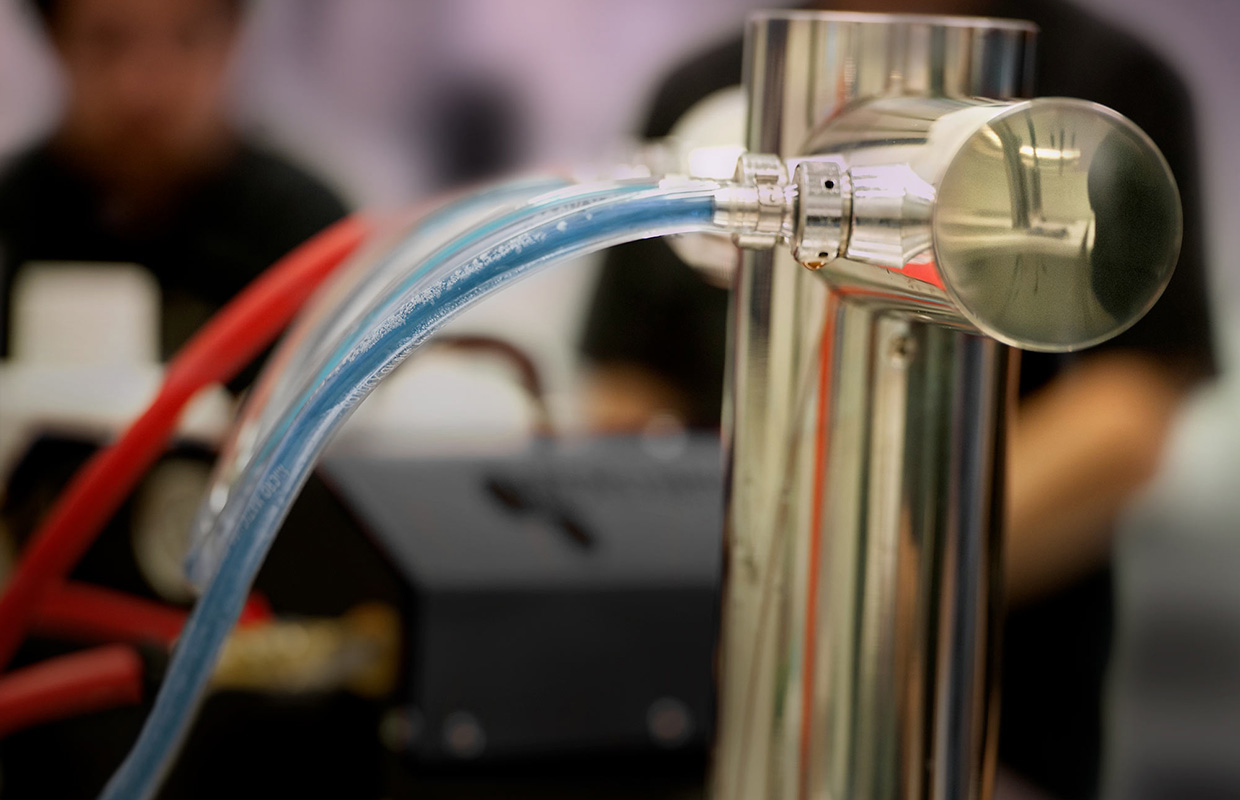

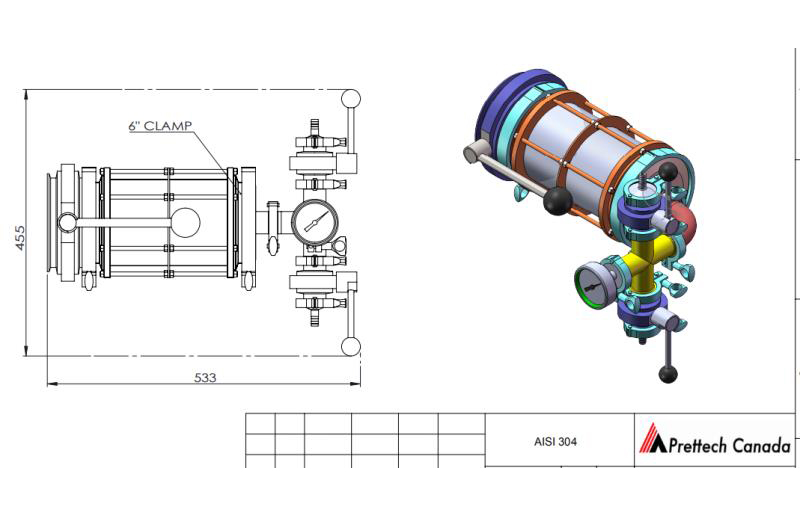

Bi-annually disassemble couplers and, if present, empty keg sensors (FOBs). After soaking parts in chemical/water mixture, rinse, then brush coupler parts clean (use soft cloth for FOBs). Inspect and replace defective seals. Lubricate internal coupler seals and reassemble both components.

Following the three-step cleaning process and guidelines will allow you to maintain your draft beer system while providing the brewery-fresh draft beer daily! Serving great-tasting draft beer will keep your customers and friends coming back for more.

For over 60 years, Micro Matic has been recognized as one of the world’s leading suppliers of draft beer equipment. Specializing in keg-to-glass technology, we offer a total solution for meeting your draft beer equipment needs. Our dedication to customer service is supported by four regional sales and distribution centers, the Micro Matic Dispense Institute for training and education, and a Certified Installer Network for draft beer installations. Want to speak with a “perfect pour” expert? Contact Micro Matic today.

Be the first to comment