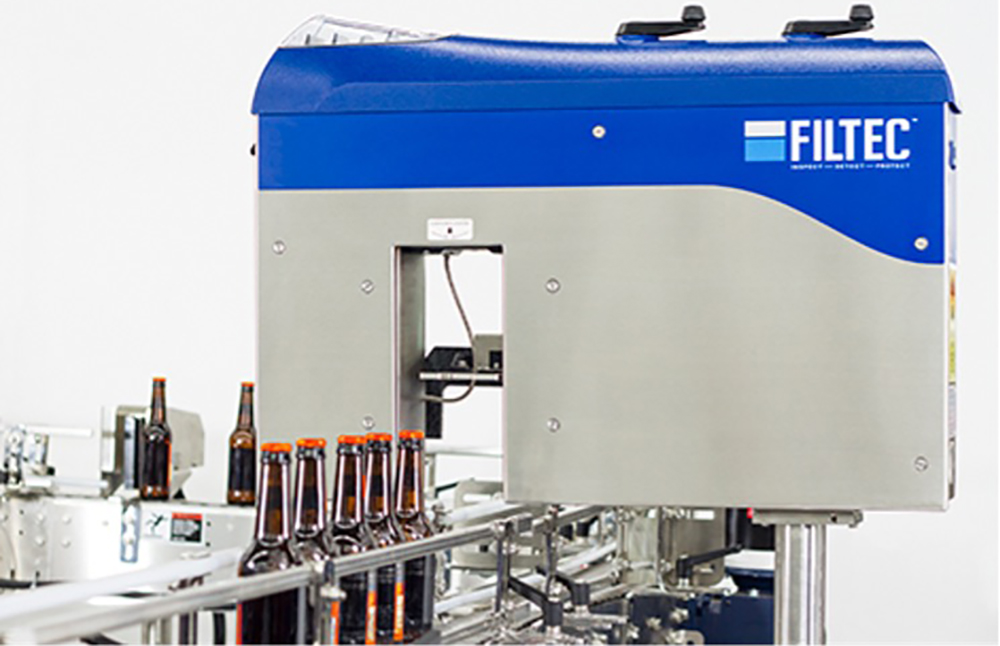

Delivering cans and bottles with precise amounts of product requires precision tools and processes. Adding a Filler Management System (FMS) to your bottling or canning line inspects and monitors filler and capper performance during production, assuring that the correct amount of liquid is in each container before it is sealed.

The ideal FMS solution should:

- Sample the filler and/or capper at production speeds without slowing or downtime

- Be positioned before the seamer for incredibly accurate fill level and valve performance measurement

- Pinpoint poorly performing filling valves and capper heads in real time

- Enables plant maintenance to focus on problem valves and capper heads during maintenance breaks

The FILTEC FMS provides all of the above, plus:

- Sampling Module – Precision sensors track bottles from the filler through to the rejector for automated sampling.

- Filler and Seamer Monitor Application (for cans) – Ability toidentify problem filler valves during can fill and analyzes under- and over-fill performance in real time.

- Filler and Closer Monitor Application (for bottles) – Continuously monitors each filler valve and presents under- and over-fill data on an operator display and accurately records the valve number and closer head number of each faulty bottle.

- Quantitative Analysis Application – Measuring the fill level range from lowfill to highfill of each filling valve and each filling process. The accumulated data provide long-term performance information for each valve and the entire filler.

- Communications -Data transfer to a host Manufacturing Execution System (MES) Input/output signal exchange with a PLC-based line control system.

Additionally, FILTEC Filler Management solutions seamlessly integrate with INTELLECT, a smart platform that offers modules to inspect closure, pressure, label, and full pack inspection. INTELLECT truly scales with and futureproofs your lines, delivering true ROI.

Learn more – go to: https://hubs.la/H0W371j0

Be the first to comment