In the world of professional brewing, consistency is key. Brewmasters strive to create exceptional products that consistently deliver on taste, aroma, and quality with every batch. Achieving such consistency can be a challenging task, especially when it comes to the critical fermentation process, the heartbeat of fermentation that creates unique flavors. With data-driven fermentation becoming more available and affordable to breweries, brewers now have a powerful tool at their disposal. The data seen in this article is collected by PLAATO Pro, with updated SG and temperature readings every 30 minutes.

Real-Time Monitoring and Analysis:

When brewers first start to collect real-time data during fermentation, they will gain access to a continuous fermentation profile from start to finish; a unique fingerprint for every batch that can support analysis between different batches and support decision-making in real-time.

Timing is Key In Creating Repeatability And Consistency Between Batches

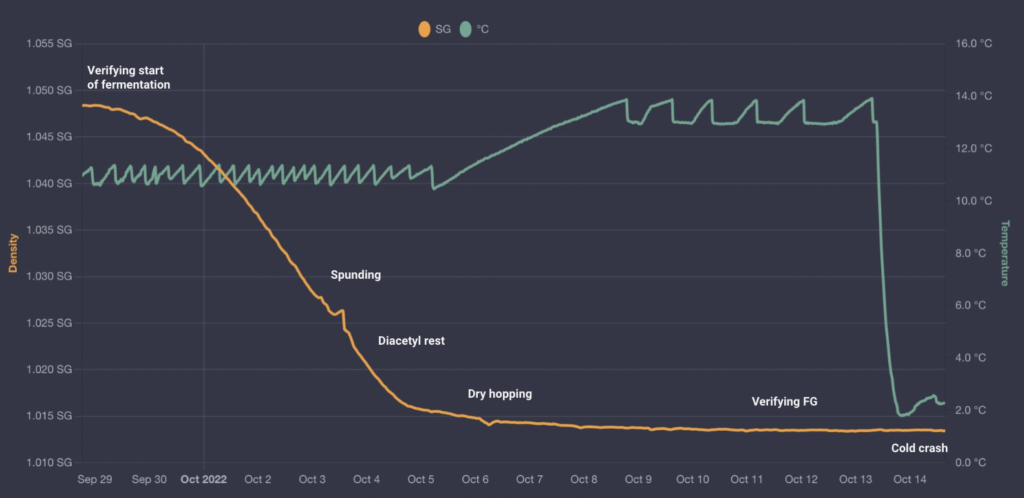

The first step is to identify the timing of each fermentation event and how changes in the recipe affect the overall fermentation profile. With PLAATO Pro you and your team can set up custom notifications based on specific SG or temperature. With real-time alerts about your fermentation progress you can:

- Start spunding at the same SG for every batch.

- Perfect diacetyl rest at the same time.

- Dry hop during the right fermentation phase.

- Harvest yeast at the right time.

How Fermentation Profiles Can Change

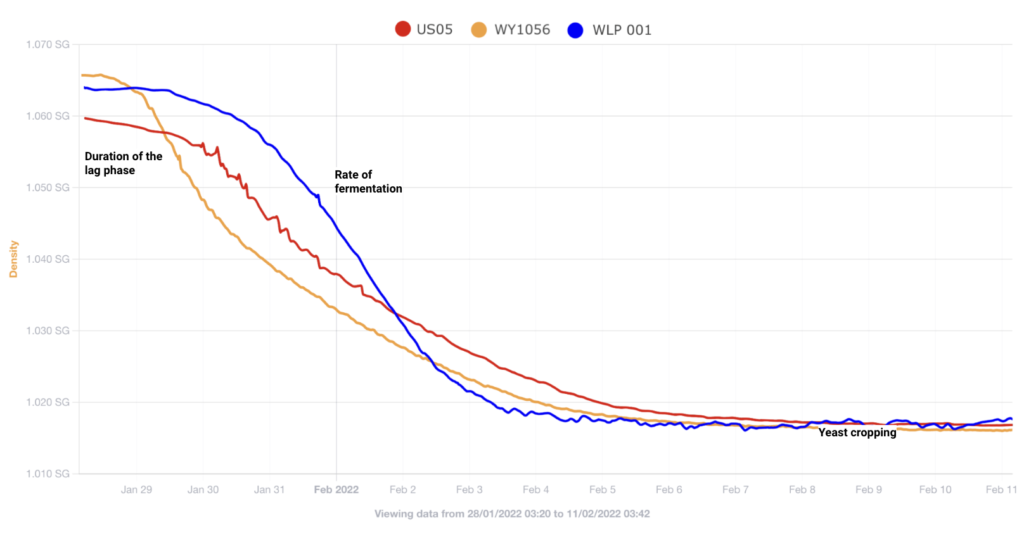

With PLAATO Pro you have the option to overlay fermentation data in the batch comparison feature to really understand how the process changes. The number of parameters that can affect the fermentation profile are almost limitless: temperature, yeast type, yeast generation, or pitching temperature are part of these. In this example, FG is approximately the same, but the dynamics of the batches are very different.

When starting to use real-time fermentation monitoring across your brewery you can build a database of fermentation profiles for your different recipes. You can learn from your best batches and your worst, and improve going forward.

About PLAATO Pro

PLAATO Pro seamlessly integrates into your brewery, turning any fermenter into a smart fermenter. The inline sensor takes density and temperature readings every 30 minutes. Real-time data is made available through our cloud solution on your smartphone and web application and can be easily shared with the whole brewing staff.

If you are interested to learn more about how real-time fermentation monitoring can impact the way you brew, contact us at [email protected] or visit us at plaato.io to learn more.

Be the first to comment