For a long time, people saw automation in a negative way, thinking it was a threat to their jobs. That automation was complex and inaccessible. On the other hand, people are increasingly realizing that this is, on the contrary, the best way to evolve and move forward in a safe way and to benefit from the expertise of the people in place where they are really needed. Anyone can put a can into a carton, but not everyone knows how to brew beer.

Many breweries are limited in their development, because even if they increase their production rate, they struggle to pack everything they produce. That’s where Consolidated Technologies come in.

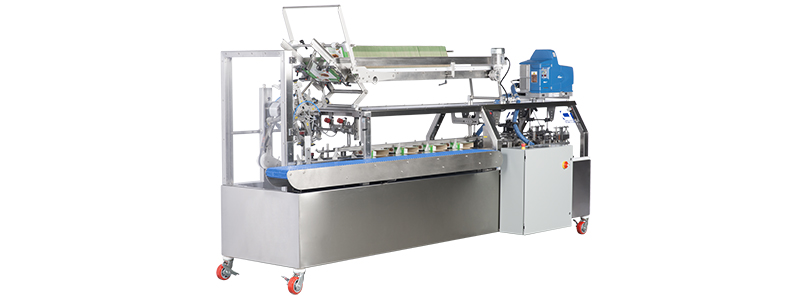

Packaging equipment, such as Cartoner, Tray Loader and Palletizer, might be the solution. We find on the market several types of models in different price range, from semi automatic to fully automatic systems.

A manual load cartoner can easily pack up to 20 cartons per minute with a single operator, while an automatic model will make up to 70 cartons per minute, with a person who will simply supervise several pieces of equipment.

Semi-automatic equipment has several advantages, including being very compact, versatile and easily movable. This allows the user to bring the machine to the necessary area when they are packing and move it elsewhere if they then want to clear the space.

The equipment can be directly linked to the production line or used separately, for example to produce mix-pack with special equipment design. Some packaging machines work in continuous motion, others in intermittent mode.

Most automatic equipment needs to be installed on adjustable legs/fixed, so it is obviously necessary to provide a permanent space. Among these are the tray packers, which will package the cartons or loose cans. At the end, everything can be palletized automatically.

There is a big productivity boom on the horizon!

Be the first to comment