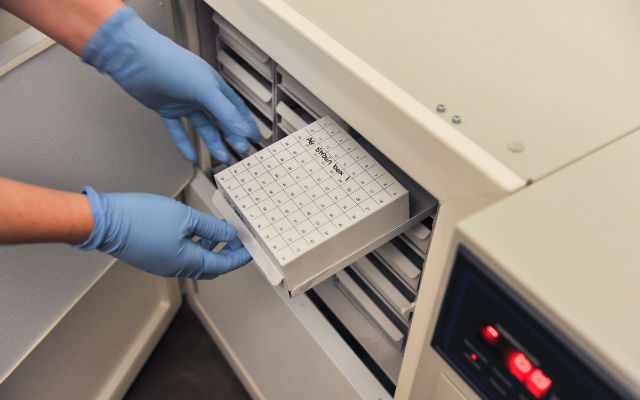

In a recent Instagram post, Dogfish Head jokingly called its cryogenic freezer a “COOL new toy,” but the addition of the unit to its lab will help the Delaware brewery work toward being more self reliant on itself when it comes to yeast management and propagation.

Currently, Dogfish Head banks its yeast with a company and orders amounts needed to use. Propagation is then done in-house. The freezer will allow the brewery to keep stocks of all of its strains and start from only a few cells said the brewery’s microbiologist, Aimee L. Garlit, PhD.

“This puts control of the entire propagation process in our hands, so we can really monitor quality throughout the process,” she said. “When you buy yeast, it comes with a COA, but you’re putting a lot of faith in someone else to give you a quality product.”

Garlit did note that it’s possible to store yeast on slants in a standard refrigerator, but slants aren’t very stable and must be continuously re-made and the risk of contamination is there the more frequently its re-done. Plus, yeast don’t like being frozen in standard household freezers that may only get to 20-below Celsius. Freezing the cells in a glycerol solution at -80C makes a stock vial that can be stored for upwards of 10 years.

Garlit can now freeze stock vials of a certain type of yeast or bacteria. The vials are fairly tiny about 1.5mL. When it’s time to prop up a strain, they scoop basically enough to fit on the head of a toothpick and streak it onto a petri dish containing growth media.

The plate will be incubated for two days as colonies form. A single colony will be picked and start a small test tube culture of 5-10mL.

Once that grows, the culture gets diluted into a larger volume in several phases eventually creating enough cells to move it into a yeast brink to grow more before pitching.

Having the freezer as a resource to prop up strains on demand gives Dogfish Head flexibility it didn’t have as much of before, Garlit noted.

“If a schedule changes, it’s a lot easier to make changes in house than to try to have something shipped quickly from thousands of miles away,” she said.

It also gives the brewery the ability to bank strains of any microorganism the lab finds interesting, whether it’s a new wild yeast or bacteria that could use for a wild beer or something that arose as a contaminant.

“Having that capability allows us to come back to it later, whether it’s to do R&D on a new beer concept or to develop a new testing method for contaminants,” she said, adding that last year, they isolated a strain of wild yeast from a tote of apple cider that produced an interesting flavor profile. They were able to propagate that and use it for a small batch of indigenous beer that was served at SAVOR.

“I foresee a lot of this type of research down the road,” she said. “There are tons of different strains commercially available, but many more that remain to be discovered.”

Be the first to comment