For over 80 years, Scott Labs’ vision has been to provide the best customer experience to the specialty beverage community. Our mission has been to advance the long-term success of the specialty beverage community by providing best-in-class products and services. We believe in education, honesty, and doing the right thing. Let us help you navigate the challenges of making hard seltzer with our products and expertise for fermentation, filtration, and shelf stability.

What’s so Hard about Fermenting Hard Seltzer?

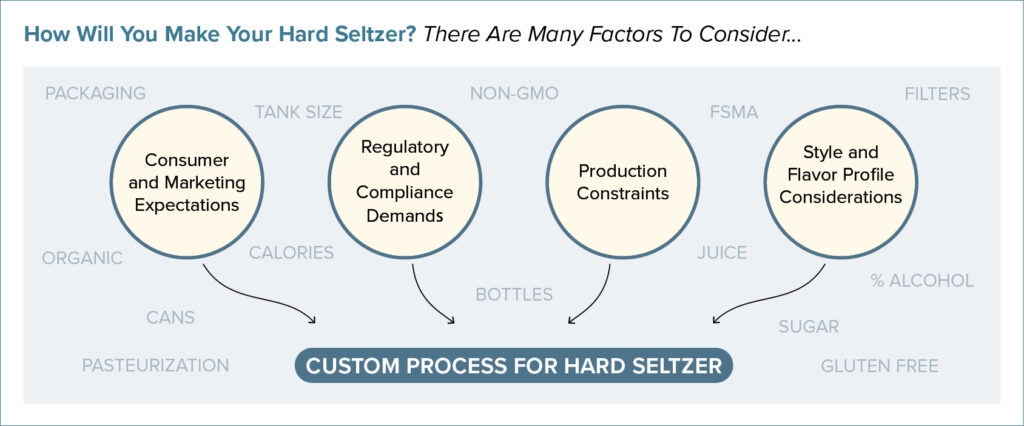

Hard seltzer and other ready‐to‐drink blends of carbonated water, alcohol, and flavoring are popular with consumers looking for low calorie, low carbohydrate, gluten‐free alcoholic beverages. Several challenges need to be addressed to produce fully fermented bases in a reasonable time frame from low nutrient sugar substrates. Without intervention, sugar fermentations are notoriously slow, unpredictable, and differ significantly from malt-, fruit-, or grape-based fermentations.

Sugar Source Matters

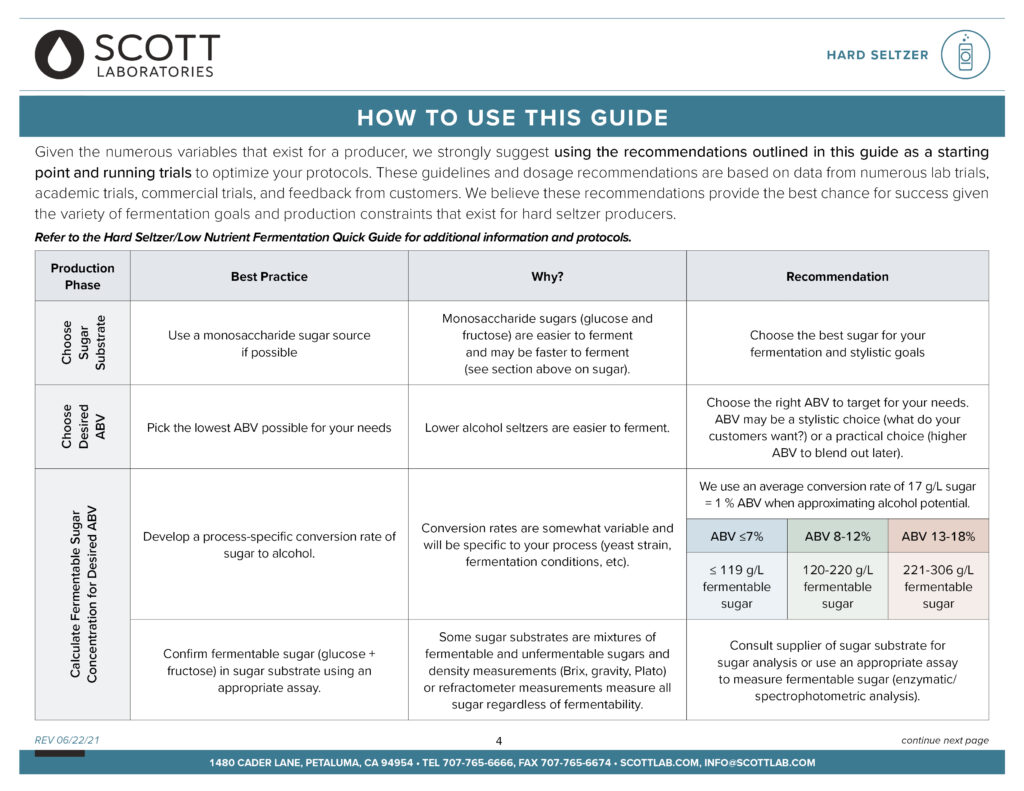

Sugar source can affect fermentation rate and monosaccharide sugars may be faster to ferment.

Common sugar sources used for seltzer fermentation include:

- Sucrose (table sugar/cane sugar) – disaccharide of glucose and fructose

- Dextrose – glucose derived from corn

- Invert sugar – mixture of glucose and fructose made by sucrose hydrolysis

- Agave – sugar from the agave plant consisting primarily of fructose

- Maltose – disaccharide of two glucose

Yeast are only able to utilize monosaccharide (single unit) sugars of glucose and fructose. For yeast to use disaccharides (sucrose, maltose, etc.) the sugar must first be broken down into monosaccharide units. Yeast’s ability to break down di- and trisaccharides into useable glucose and fructose varies and is strain dependent. Most yeast can break down sucrose into glucose and fructose by producing invertase. However, in difficult fermentation conditions, the additional yeast energy required to produce invertase may slow fermentation. Other sugar and yeast strain combinations may not be compatible and enzyme additions may be necessary to break down larger sugar molecules into glucose and fructose.

Yeast and Nutrients Matter

NUTRIENTS ARE IMPORTANT

Yeast require a balance of vitamins, minerals, survival factors and nitrogen in addition to an energy (sugar) source to properly grow and survive during fermentation. Malt- and fruit-based ferments typically have ample amounts of nutrients, but sugar-based ferments are nutrient deserts and supplementation is essential. Nutrients decrease fermentation time and promote complete (dry) ferments.

NOT ALL NUTRIENTS ARE THE SAME

Nitrogen is one of the most important yeast nutrients. Yeast use assimilable nitrogen to synthesize cellular proteins, enzymes, and nucleic acids. Without adequate nitrogen, fermentation slows because yeast cannot maintain their cell function or reproduce.

Inorganic nitrogen sources, such as diammonium phosphate (DAP) or urea, can be used to overcome some nitrogen deficiencies. However, these chemicals cannot be used in organic-labeled seltzers and, in the case of urea, there is a high risk of ethyl carbamate formation, a compound classified by the FDA as a probable carcinogen. We recommend rehydration with GO-FERM PROTECT EVOLUTION, and additions of NUTRI2 during fermentation.

YEAST DOSAGE MATTERS

Adequate yeast dosage produces better results and higher gravities require higher dosage rates.

High gravity seltzers are especially difficult to ferment due to increased osmotic pressure from high sugar at the start of fermentation and elevated alcohol at the end of fermentation. Even with nutrient supplementation, sugar ferments struggle when dosage rates are too low.

YEAST STRAIN MATTERS

Strain kinetics and sensory impact determine suitability for seltzer. Yeast strains vary in alcohol tolerance, nutrient requirement, temperature tolerance, ability to breakdown disaccharides, fermentation speed, and many other traits. Many strains are not robust enough to ferment seltzer bases. Therefore, VI-A-DRY BOSS™ yeast is recommended for its strong fermentation kinetics, low nutrient needs, neutral sensory effects, and ability to breakdown sucrose and other sugars.

Fermentation Temperature Matters

Identifying optimal fermentation temperature can be tricky. Temperature affects fermentation rate, yeast health, and sensory impact. Despite its importance, the numerous factors affecting low-nutrient sugar fermentations make it difficult to provide clear temperature guidelines. Yeast strains vary in their temperature tolerance and can be stressed when fermenting at the upper or lower end of their recommended temperature range, especially as alcohol increases. Though fermentation is faster at warmer temperatures, the risk of yeast stress leading to stuck ferments and off-odors also increases. Finding a fermentation temperature that balances fermentation speed and yeast health will likely require experimentation for any given process.

Learn More

Visit us at scottlab.com/seltzer to download our free best practices guides to hard seltzer fermentation and filtration as well as view our entire portfolio of seltzer-related products including:

- New seltzer-specific yeast

- New nutrient applications

- Complete filtration solutions

- Beverage stabilization with Velcorin® — an alternative to pasteurization and preservatives

Be the first to comment