In recent years, the craft beer industry has witnessed a significant surge in popularity, with microbreweries popping up across the globe. Among this growth, ensuring operational efficiency and cost-effectiveness becomes paramount for microbreweries to thrive in a competitive market. One often overlooked aspect of brewery operations is the utilization of compressed air systems, which play a crucial role in various brewery processes such as bottling, packaging, and fermentation.

Investment Feasibility

When considering such investments, microbreweries must assess the practicality of implementing compressed air systems. Leading industrial equipment providers offer comprehensive solutions for optimizing compressed air systems tailored to brewery needs. The most flexible and risk-free option is establishing an energy-usage monitoring system, like Atlas Copco’s SMARTLink. These solutions ensure energy efficiency and cost-effectiveness without the need for specific platforms.

A key aspect of investment feasibility lies in evaluating the total cost of ownership (TCO) versus the potential benefits. Microbreweries can accurately estimate the initial investment required for installing compressed air systems while forecasting operational costs over the system’s lifespan. Factors such as energy consumption, maintenance expenses, and system reliability are carefully analyzed to provide a clear picture of the economic implications without reliance on proprietary platforms.

Determining the return on investment is crucial for microbreweries looking to justify their capital expenditure on compressed air systems. Breweries can use advanced modeling techniques to calculate the ROI based on energy savings, productivity gains, and reduced maintenance costs.

Microbreweries can significantly lower operational expenses by transitioning to energy-efficient compressed air solutions. Reduced energy consumption translates to substantial cost savings over time, contributing to a favorable ROI. Enhanced system reliability and performance can lead to increased production output and improved product quality, further bolstering the economic benefits.

Nitrogen Savings with Onsite Generation

In addition to compressed air, nitrogen plays a vital role in brewery operations, particularly in packaging and preserving beer quality. Traditionally, some breweries have relied on nitrogen cylinders, which leads to recurring costs and logistical challenges. However, onsite nitrogen generation offers a cost-effective and sustainable alternative.

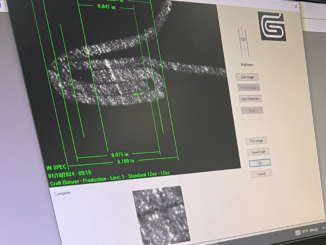

Nitrogen generation systems utilizing membrane and pressure swing adsorption (PSA) technologies offer microbreweries the ability to produce high-purity nitrogen onsite. Breweries eliminate the need for nitrogen cylinders by generating nitrogen as needed, reducing operational expenses and carbon footprint. Onsite nitrogen generation also ensures a consistent supply, enhancing process control and product quality.

By generating nitrogen as needed, microbreweries eliminate the need for nitrogen cylinders, thereby reducing operational expenses associated with purchasing, transporting, and storing these cylinders, minimizing logistical challenges and safety concerns related to handling pressurized gas cylinders. This aligns with the growing emphasis on sustainability and environmental responsibility within the brewing industry and demonstrates the brewery’s commitment to reducing its environmental impact.

Unlike nitrogen cylinders, which run out unexpectedly, onsite nitrogen generation systems are programmed to meet the brewery’s specific nitrogen demand, ensuring uninterrupted production processes. This consistency in nitrogen supply is crucial for various brewery operations. By maintaining optimal nitrogen levels, breweries can achieve better control over carbonation levels, foam stability, and flavor preservation, ultimately enhancing their products’ overall quality and reputation for producing high-quality beer.

The economic analysis of compressed air systems reveals significant potential for microbreweries to enhance operational efficiency and reduce costs. Breweries can achieve substantial savings and improve overall profitability by leveraging technology-driven solutions such as SMARTLink and onsite nitrogen generation. As the craft beer industry continues to evolve, investing in optimized compressed air infrastructure emerges as a strategic imperative for microbreweries seeking sustainable growth and competitiveness in the market.

Find out more about Atlas Copco here.

Be the first to comment