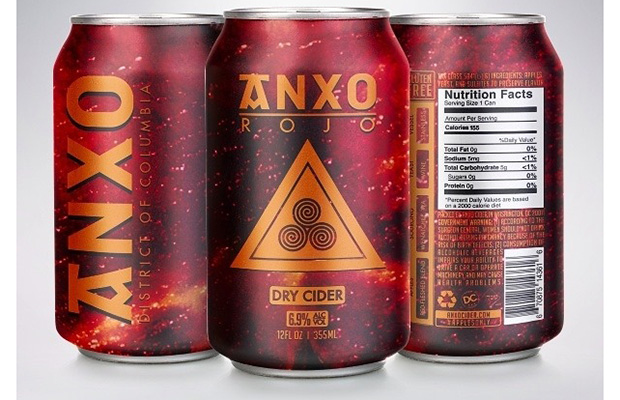

There are many little things about process, equipment and such that Gregory Johnson has implemented at ANXO that has helped in the cidery’s day-to-day operations and the Head Cidermaker for the Washington DC facility said he could have a great in-depth discussion on all of them.

“But plain and simple, our canning line is the most important thing we have done,” he said. “Buying our own canning line was the biggest thing we could do for ourselves.”

Johnson noted that for the cidery to be able to have control over a process and its own equipment has been a challenge and a blessing.

“We are not at the whims of a mobile canning company,” he pointed out. “Who knows what was canned last on their line, but now able to reign that in.”

ANXO’s line is fast and fills under counter pressure, yielding better canning results, Johnson said.

“The canning line is also compatible with steam cleaning, so we integrate that with our CIP procedures,” he said.

“There is a laundry list of other things we need to improve our cidery, but given our youth and rapid expansion we will get there.”

John Kowchak, the president and founder of Original 13 Ciderworks added that although the Philadelphia cidery doesn’t have its own canning line yet, its latest purchase has been a 1,000-gallon brite tank.

“Canning is the biggest way for us to get our product out to a wide market, and right now we are maximizing the ability of our mobile canner,” Kowchak said. “Since we can’t increase the number of canning runs, the next best thing is to double the amount of cider we can on each run.”

Kowchak noted that by selling a quality beverage that customers come back to time and time again is a major key as well.

Be the first to comment